A Guide to Commercial Rotating Pizza Ovens in Los Angeles

Share

If you're running a high-volume kitchen in Los Angeles, a commercial rotating pizza oven isn't just a piece of equipment—it's your secret weapon. These ovens use an automated rotating deck, which means every single pizza gets cooked perfectly and evenly without anyone needing to manually turn it. The whole point is to boost efficiency, reduce labor costs, and slash customer wait times, making it a smart move for any busy L.A. eatery.

The Secret Weapon of L.A.'s Top Kitchens

In the cutthroat Los Angeles food scene, it all boils down to two things: consistency and speed. It doesn't matter if you're slinging pies from a food truck in Silver Lake or running a high-end spot in Beverly Hills; getting a perfect product out the door fast is everything. This is where a commercial rotating pizza oven stops being just a machine and becomes a serious competitive advantage.

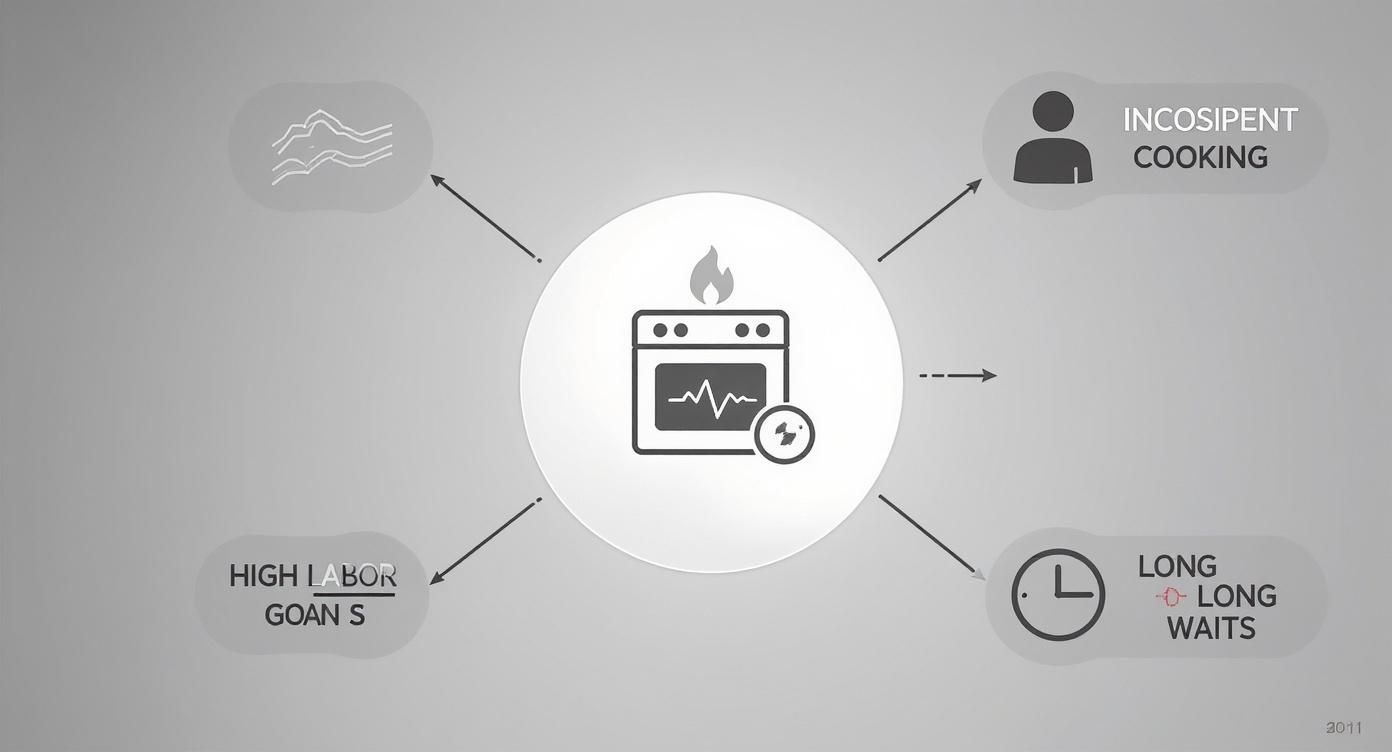

Think about the daily headaches in most L.A. kitchens. Inconsistent cooking means wasted food and customers who won't come back. High labor costs eat away at your margins, especially when you have skilled staff just watching an oven. And long waits during a rush? That's just lost money and bad Yelp reviews waiting to happen.

A rotating oven tackles these problems head-on. By automating the bake, it guarantees every item gets the exact same amount of heat. This frees up your crew from babysitting pizzas so they can focus on prep, plating, and taking care of customers. The result is a flawless, repeatable product that builds a great reputation and keeps people coming back for more.

How Rotating Ovens Compare

Sure, traditional deck ovens and conveyor ovens have their place, but a rotating oven offers a unique mix of quality and efficiency that really sets it apart. It gives you the beautiful, artisanal results of a deck oven combined with the hands-off consistency of a conveyor belt. It's the best of both worlds for a modern kitchen.

This unique combination allows L.A. restaurants to produce high volumes of top-quality food, from classic Neapolitan pizza to perfectly charred naan for a Thai curry dish or crisp flatbreads for a Japanese izakaya.

To see what I mean, let's put them side-by-side. This quick comparison shows how each oven type stacks up in the areas that matter most to a busy commercial kitchen, whether it's a food truck needing lightning-fast service or a restaurant juggling a diverse menu.

Rotating Ovens vs Traditional Ovens At a Glance

Here’s a simple breakdown of how these three popular oven types perform under pressure.

| Feature | Rotating Oven | Deck Oven | Conveyor Oven |

|---|---|---|---|

| Consistency | Excellent – Automated rotation ensures perfect, even cooking every time. | Variable – Requires skilled labor to manually turn pizzas and manage hot spots. | Good – Produces a very consistent product but lacks artisanal char. |

| Labor Requirement | Low – Load the pizza, set the timer, and unload when done. | High – Needs a dedicated, experienced operator for best results. | Low – Simple to operate with minimal training required. |

| Speed | Very Fast – Combines intense heat with even exposure for rapid cooking. | Moderate – Slower cook times and requires manual handling for each pizza. | Fast – Designed for high-speed, continuous production lines. |

| Versatility | High – Excels with various cuisines, from Mexican tortillas to Korean pajeon. | Moderate – Best suited for traditional pizza and bread baking. | Low – Primarily designed for one type of product, usually pizza. |

As you can see, the rotating oven hits a sweet spot, delivering top-tier consistency and speed with minimal labor. It's an incredibly versatile machine that can handle much more than just pizza, making it a valuable asset for almost any L.A. kitchen looking to step up its game.

How Rotating Ovens Deliver Perfect Results Every Time

To get a handle on what makes a commercial rotating pizza oven so special, just imagine a carousel. But instead of horses, you have pizzas taking a slow, predictable trip through a zone of perfect, even heat. That simple concept is exactly why these ovens churn out flawless results, taking all the guesswork and frantic turning out of the equation. It's automation built for pure consistency.

The real magic is in how a few key parts work in harmony. The rotating stone deck is the floor of the carousel, making sure every single inch of the pizza gets the exact same blast of heat from underneath. This one feature kills hot spots. That means no more pies that are torched on one side and raw on the other. Your crew can just load, set the timer, and unload without constantly yanking the door open.

This whole setup is designed to solve some of the most frustrating problems in any kitchen.

As you can see, things like uneven cooking, high labor costs, and long ticket times are the exact bottlenecks a rotating oven is built to eliminate.

The Dynamic Duo of Heat

That consistent cook is powered by a heat source, which can be gas, wood, or electric. Whatever the fuel, it generates intense heat that floods the oven's chamber. This is where the heat-trapping dome steps in. A lot like the roof of a classic brick oven, the dome soaks up all that energy and radiates it right back down onto the top of the food.

This creates a powerful one-two punch of cooking power.

- Radiant Heat: This is the heat that beams down from the dome and walls, perfectly melting the cheese and crisping up the toppings.

- Conduction Heat: This is the direct heat that transfers from the hot rotating stone right into the dough, giving you that incredible crispy-but-chewy crust.

Some models even add a fan for forced air, bringing in a third type of heat transfer: convection. If you've ever used other professional equipment, you know how much this speeds things up. While a rotating oven is a unique beast, understanding the basics of a standard commercial convection oven helps you appreciate how moving hot air leads to faster, more even results.

More Than Just Pizza

This leap in technology is precisely what makes rotating ovens so valuable here in the L.A. food scene. That consistency is a game-changer, not just for pizzerias, but for any spot that needs perfectly cooked flatbreads, and fast.

Think of a packed Mexican restaurant in East L.A. that needs hundreds of perfectly puffed tortillas during the dinner rush, or a Korean spot in K-Town grilling flatbreads for appetizers. A rotating oven ensures every single one comes out identical, without tying up a skilled cook.

This reliable, automated cooking process is the foundation of the oven’s value. It transforms a chaotic, hands-on job into a smooth, predictable operation. By mastering heat and motion, these ovens let L.A. restaurants and food trucks serve better food faster. You can serve more customers and build a reputation for quality, one perfect pizza at a time. This isn't just about making a great pie; it's about building a more efficient and profitable kitchen.

Choosing the Right Oven for Your LA Restaurant

Picking the right commercial rotating pizza oven for your Los Angeles restaurant is about more than just buying a piece of equipment. It’s a decision that has to match your menu, your kitchen space, and the very vibe of your brand. The whole process really kicks off with the most basic question: what’s your heat source? Gas, wood, and electric all bring something different to the table, and your choice will shape your kitchen’s workflow and the food you serve every day.

Think of the fuel type as the main ingredient in your signature dish. It dictates the flavor profile, the cooking style, and even the experience you create for your customers. For many L.A. spots, the decision is a no-brainer right from the start.

A busy Thai restaurant cranking out flatbreads needs the speed and consistency of gas. On the other hand, an artisan pizzeria in Venice Beach might build its entire reputation around the incredible aroma of a wood-fired oven. The heat source is truly the heart of the machine.

Gas Fired: The King of Convenience

Gas-fired rotating ovens are the undisputed workhorses of the modern L.A. kitchen. They're just incredibly convenient. You get fast heat-up times and can dial in the perfect temperature with the turn of a knob. That kind of control is a lifesaver for restaurants with diverse menus, letting chefs pivot from searing-hot pizza to lower-temp baking without missing a beat.

Imagine a packed Chinese restaurant in the San Gabriel Valley during the dinner rush. A gas oven can flawlessly cook hundreds of scallion pancakes, getting each one perfectly crisp without the constant attention a live fire demands. For pure efficiency and reliability, gas is tough to beat.

Wood Fired: The Soul of Authenticity

Let's be honest, for a lot of people, nothing can replace the smoky, authentic flavor that only a real wood-fired oven can deliver. This is about more than just cooking—it's theater. The crackle of the fire and that unmistakable aroma become a centerpiece of the restaurant's atmosphere, signaling quality and tradition to every customer who walks in.

And it’s not just for pizzerias anymore. Commercial wood-fired pizza ovens are a hot market for a reason. Projections show this segment is set to grow by about USD 15.17 million between 2025 and 2029. Why? Because they’re so versatile. You can roast a chicken, toast a panini, or bake bread, letting a kitchen really stretch its creative legs.

Electric: The Champion of Precision and Placement

Electric rotating ovens are the problem-solvers. They’re the perfect fit for kitchens where space is tight or ventilation is a headache. For food trucks, basement kitchens, or spots in historic buildings with strict regulations, they are often the only way to go. Many models are completely ventless, which means you can skip the huge expense of a professional hood installation.

But it’s not just about convenience. Electric ovens offer almost surgical precision. The heat is consistent and dry, which is ideal for more delicate baking. A trendy Korean spot in K-Town could use an electric oven to bake perfectly uniform, cheese-stuffed rice cakes, getting a consistent texture that's tough to nail with the fluctuating heat of a wood fire.

Single vs. Multi-Deck Configurations

Once you’ve settled on a heat source, you need to think about the oven’s layout. Choosing between a single or multi-deck model is all about your kitchen’s output and daily flow.

-

Single-Deck Ovens: This is what you’ll see most often. They’re perfect for the majority of restaurants, even high-volume ones. The large rotating deck can often handle several pizzas or other items at once, giving you a ton of output from one machine.

-

Multi-Deck Ovens: If your demand is off the charts, a multi-deck oven is the ultimate production powerhouse. Each deck can run at a different temperature, so you could be baking pizzas at high heat on one level while cooking something else at a lower temp on another.

That kind of flexibility is how you get the most out of your investment. An organized kitchen that pairs the right oven with a smart prep area can boost efficiency like crazy. In fact, matching your oven with a great commercial pizza prep table is one of the smartest moves you can make to keep up with the speed of a rotating oven.

Understanding the Metrics That Matter for Your Business

A commercial rotating pizza oven is far more than just another appliance in your kitchen; it's the engine that can drive your business forward. To really see its value, you need to look past the shiny features and focus on the hard numbers—the performance metrics that directly boost your bottom line. These numbers tell the real story of how this machine can make your Los Angeles restaurant more profitable.

The core metrics—capacity, cook time, temperature, and fuel use—all translate into real-world results. A faster cook time means you’re serving more customers during a slammed lunch rush. Higher capacity means you can handle big catering orders without breaking a sweat. It’s all about turning great technology into solid revenue.

Think about a busy food truck parked in Downtown L.A. For them, these numbers are everything. Slashing customer wait times from ten minutes down to three isn't just a small improvement; it's the difference between making a sale and watching a potential customer walk away.

Capacity and Cook Time: The Revenue Multipliers

The two numbers that should matter most to any operator are capacity (how many pizzas it holds) and cook time. Commercial rotating ovens are engineered to blow these numbers out of the water. With cook times often dropping between 90 to 180 seconds, the potential throughput is just incredible.

This speed dramatically increases your total output, which we measure in pizzas per hour. A standard deck oven might push out 20-30 pizzas an hour with one person working it constantly. A rotating oven, though, can easily double or even triple that output, and with less direct labor.

Let's run a quick scenario for that L.A. food truck:

- Lunch Rush: 2 hours (12 PM - 2 PM)

- Average Pizza Price: $15

- Old Oven Output: 25 pizzas/hour

- New Rotating Oven Output: 70 pizzas/hour

In just that two-hour window, the new oven could generate an extra $1,350 in revenue. Over a week, that's a massive boost to the bottom line, all from a single equipment upgrade.

Temperature Range: Versatility for Diverse Menus

While speed is king for pizza, a wide temperature range unlocks your menu's creativity. Most commercial rotating ovens can operate anywhere from a low-and-slow 500°F up to a blistering 900°F. This kind of flexibility is a huge advantage for L.A. restaurants known for their diverse cuisine.

A Japanese izakaya can use high heat to quickly char flatbreads for appetizers, then lower the temperature to gently bake delicate fish dishes. This turns a "pizza oven" into a multi-purpose workhorse that adds value across your entire menu.

This versatility means you get more out of a single piece of equipment. Instead of needing separate ovens or broilers, you can roast, bake, and finish dishes all in one spot. This frees up valuable space in a tight kitchen and maximizes your investment.

Fuel Efficiency: The Hidden Savings

Finally, we have to talk about fuel efficiency. Modern rotating ovens are built with top-notch insulation and heat retention. Because the cooking chamber is sealed and the deck rotates, the door stays shut, keeping the heat locked inside where it belongs.

Over time, this leads to significant savings. An efficient gas model uses less fuel to stay hot, while a wood-fired version requires far less wood. These operational savings add up month after month, lowering your overhead and making your business more profitable. It’s a smart investment, not just another expense.

Performance Snapshot of Commercial Rotating Ovens

To help you match an oven to your specific business needs, we've put together a breakdown of typical performance metrics. Whether you're a small cafe testing a new pizza menu or a high-volume pizzeria, this data will help guide your decision.

| Oven Size (Deck Diameter) | Capacity (Pizzas at once) | Output (Pizzas per hour) | Average Cook Time | Best For |

|---|---|---|---|---|

| Small (40-48 inches) | 4-6 | 60-90 | 2-3 minutes | Food trucks, cafes, restaurants adding a small pizza menu. |

| Medium (56-60 inches) | 7-10 | 100-150 | 90-120 seconds | Mid- to high-volume restaurants and dedicated pizzerias. |

| Large (72+ inches) | 12-18+ | 200+ | 90-120 seconds | Large-scale production, ghost kitchens, high-demand venues. |

Choosing the right size is all about balancing your current output with your growth goals. This table gives you a solid starting point for figuring out which model will be the best fit for your kitchen.

Navigating Installation in Your Los Angeles Kitchen

Bringing a new commercial rotating pizza oven into your kitchen is a huge deal, but the real work starts way before it ever shows up on a delivery truck. Getting the planning right is everything—it’s what separates a smooth launch from a series of costly, frustrating headaches. For any restaurant or food truck in Los Angeles, that means getting serious about your space, your utilities, and the local rules of the road.

First thing's first: map out the oven's footprint. These things are beasts, and you need to account for more than just the unit itself. You've got to leave enough clearance on all sides for safety and for your maintenance crew to get in there when they need to. This is especially true in L.A.'s notoriously tight food trucks, where every single inch is pure gold.

Mastering Your Kitchen Layout

A smart kitchen layout is the only way you'll ever cash in on your new oven's incredible speed. The goal is a seamless workflow, a straight shot from prep to cook to plating. That means putting your oven right where it needs to be, next to key stations like your commercial refrigerators and pizza prep tables, to cut down on wasted steps for your staff.

Think about how the flow works for your specific L.A. spot:

- For Restaurants: You’ll want the oven where it’s an easy hand-off from both the prep line and the pass. This keeps the whole operation moving and stops those dreaded bottlenecks when you're slammed.

- For Food Trucks: A straight line is usually your best bet. Stick the oven at one end of the truck and have the prep stations lead right up to it. It’s a logical, efficient assembly line on wheels.

A good workflow isn't just about moving faster; it's about staying safe. When you have a clear, open path to and from that hot oven, you drastically cut down the risk of accidents. It helps your team work with confidence, even when the pressure is on.

Complying with Los Angeles Codes

This is where your planning really gets put to the test. Los Angeles County has some of the toughest health and fire codes in the country, and you absolutely can't afford to get this wrong. Ventilation is a huge one. An improper system isn't just a violation; it's a massive safety hazard. Gas and wood-fired ovens need very specific hood and exhaust systems, and they must be installed and inspected by pros.

Trying to cut corners here can lead to failed inspections, eye-watering fines, and major delays that can stop your business cold. It's so important to work with suppliers and installers who know L.A. regulations inside and out. They’ll make sure your entire setup is buttoned-up and compliant from day one, saving you a world of stress and money.

Utility Hookups and Professional Installation

Finally, your oven needs its fuel. Gas models have to be hooked up to a dedicated gas line by a licensed professional, and many electric ovens require a heavy-duty, high-voltage connection. Thinking about a DIY install? Don’t. It’s not just dangerous—it can void your warranty and get you in hot water with the city.

- Gas Hookups: These have to meet strict requirements for pressure and pipe size.

- Electrical Connections: A qualified electrician needs to handle this to ensure everything is safe and the oven functions correctly.

- Ventilation Systems: This is specialized work. The install has to meet all the fire suppression and air quality standards.

Always, always go for a professional installation. An expert will make sure every connection is rock-solid, the oven is perfectly level so the deck rotates evenly, and all the systems are calibrated to give you the best performance possible. Investing in a pro install is how you protect your new equipment, your staff, and your entire business. It's the final, non-negotiable step to unlocking everything a commercial rotating pizza oven can do for you.

Calculating Your Total Investment and Long-Term ROI

When you're looking at a commercial rotating pizza oven, the sticker price is just the beginning of the story. To really understand what it’s worth to your Los Angeles business, you need to look at the total cost of ownership and, more importantly, the long-term return on investment (ROI). This means adding up every single cost, from the day it arrives to the day-to-day grind.

The upfront investment is the most obvious piece. You've got the oven itself, the professional delivery, and the all-important installation and ventilation systems needed to satisfy L.A. County codes. Those numbers can jump around depending on the oven's size and what kind of fuel it uses, but they're the foundation of what you'll pay out of pocket.

Uncovering the Long-Term Value

Once that oven is fired up and running, the real financial picture starts to take shape. You'll have ongoing costs like fuel—gas, wood, or electricity—and the routine maintenance that keeps it humming. But honestly, those costs are often small potatoes compared to the money a rotating oven can bring in. It's an investment that truly pays you back.

The first place you'll see a return is in drastically reduced labor costs. With a deck that turns on its own, you don't need a highly skilled pizzaiolo glued to the oven, turning pies. That person is now free to handle other critical kitchen tasks, which makes your whole operation run smoother and keeps your payroll in check.

A commercial rotating pizza oven transforms a high-touch, variable process into a predictable, low-labor system. This consistency not only saves money on staffing but also minimizes food waste from burnt or undercooked products, boosting your profit margins on every dish sold.

Boosting Revenue and Accessibility

Then there's the sheer volume. A rotating oven cooks perfectly and quickly, meaning you can serve more people, especially when your restaurant or food truck is slammed during peak hours. More pizzas out the door means more revenue in the bank. This kind of performance is a big reason the global commercial pizza oven market is on fire, valued at around USD 2.19 billion in 2024 and still growing. The commercial side of things, powered by restaurants and food trucks, makes up over 70% of that market. You can explore more data about the growing pizza oven market.

For a lot of L.A. businesses, financing is what makes this kind of equipment a reality. Leasing and financing options let you get the oven you need without dropping a huge amount of cash all at once. This frees up money for other must-haves, like stocking your kitchen. After all, managing your inventory with solid cold storage is just as vital—which is why understanding your options, like a walk-in cooler and freezer combination, is key to a well-oiled machine. These financing strategies make a big upgrade like this a practical move for both brand-new spots and established L.A. restaurants.

Common Questions from LA Restaurant Owners

When you're thinking about a major equipment upgrade, you're going to have questions. It’s only natural. For restaurant and food truck owners all over Los Angeles looking at commercial rotating pizza ovens, a few key concerns always seem to come up. Let's get you some straight answers so you can make the right call for your business.

How Much Maintenance Does a Rotating Oven Need?

These ovens are built tough for the daily chaos of a commercial kitchen, so they need surprisingly little day-to-day maintenance. The most important thing is routine cleaning, just like with any other piece of cooking equipment. For wood-fired models, that means clearing out ash and always keeping the stone deck free of any food debris.

Beyond that, getting a professional check-up once a year is a really smart move. Have a technician inspect the motor, the rotating mechanism, and all the gas or electrical parts. This bit of preventative care keeps the oven running like a top for years and helps you avoid a breakdown during a busy dinner rush.

Can I Cook More Than Just Pizza in It?

Absolutely, and this is where it gets exciting for the diverse L.A. food scene. That consistent, high heat is a game-changer for a ton of different dishes from all kinds of cuisines.

- Mexican: You can cook and puff up fresh tortillas in seconds.

- Thai: Get the perfect char on flatbreads to go with your curries.

- Japanese: Sear small plates or give dishes a beautiful, smoky finish.

- Korean: Bake up some incredible cheese-filled rice cakes or crisp up savory pancakes.

The versatility of commercial rotating pizza ovens is a huge plus. One piece of equipment can open up your menu and support a ton of creativity, making it an incredibly valuable player in any kitchen.

What’s the Real Difference Compared to a Conveyor Oven?

They both offer a type of automation, but how they cook—and the final product—are worlds apart. Conveyor ovens are pure production machines, pushing food through a heated chamber on a belt. They’re fast, but the result is often uniform and lacks that artisanal touch.

A rotating oven gives you the best of both worlds: the authentic, hearth-baked quality of a classic deck oven combined with the consistency of automation. The rotating stone deck is what delivers that perfect crispy crust and beautifully melted top that a conveyor oven just can't touch.

Now, conveyor ovens have their place, especially in super high-volume spots. The pizza conveyor oven market was valued at about USD 730.7 million globally in 2025, a number driven by their speed in fast-food chains. You can discover more insights about the commercial pizza oven market and its different segments. But for any restaurant that cares about top-tier quality without giving up speed, a rotating oven is the clear winner.

Ready to see how a rotating oven could transform your kitchen’s output and the quality of your food? The experts at Los Angeles Restaurant Equipment can walk you through the options and help find the perfect model for your space, menu, and budget. Explore our full range of professional kitchen solutions and find the right equipment to help your business grow. Visit us at https://losangelesrestaurantequipment.com.