Converting from Natural Gas to Propane for LA Restaurant Kitchens

Share

For most commercial kitchen appliances, making the switch from natural gas to propane is a pretty straightforward job. It's all about swapping out a few key parts to handle propane's higher pressure and energy density. This simple change allows Los Angeles restaurants and, more importantly, Los Angeles food trucks to run their high-performance restaurant equipment anywhere, completely untethered from fixed gas lines. The trick is to always use the correct manufacturer-approved conversion kit—that’s non-negotiable for safety and performance.

Why LA Restaurants Convert to Propane

In the cutthroat Los Angeles food world, being able to pivot is everything. For so many restaurant owners and food truck operators I talk to, converting equipment from natural gas to propane isn't just a technical fix. It’s a savvy business move that opens up a world of flexibility, power, and freedom, impacting everything from their ranges to their commercial refrigerators and freezers.

This move is absolutely essential for the mobile kitchens, pop-up concepts, and catering businesses that really define the LA food scene. Think about it: a Korean BBQ truck drawing huge crowds in Koreatown or a Thai food pop-up at a Silver Lake street fair. Being able to fire up powerful restaurant equipment without hunting for a gas line is a massive advantage.

Embracing True Kitchen Portability

The number one reason for the switch? Portability. Natural gas demands a physical pipeline connection, chaining your ranges and fryers to one spot. Propane, on the other hand, comes in portable tanks, giving you a self-contained power source to take your entire kitchen on the road.

This freedom means you can:

- Operate Anywhere: Set up shop at festivals, private events, farmers' markets, or any spot that's off the natural gas grid.

- Launch Mobile Concepts: Power a full-on food truck with the same heavy-duty commercial equipment you'd find in a brick-and-mortar place.

- Expand Catering Services: Pull off incredible off-site events, from fancy weddings to corporate lunches, without ever sacrificing cooking power.

The Power and Efficiency Advantage

Besides mobility, propane packs a serious punch. Let's take a quick look at how the two fuels stack up.

Natural Gas vs Propane At a Glance for Your Kitchen

| Characteristic | Natural Gas | Propane (LPG) |

|---|---|---|

| Energy Density | ~1,030 BTU per cubic foot | ~2,516 BTU per cubic foot |

| Delivery Method | Fixed pipeline to the building | Portable, refillable tanks |

| Pressure | Low pressure (~0.25 PSI) | High pressure (100-200 PSI) |

| Best For | Brick-and-mortar restaurants | Food trucks, catering, pop-ups |

| Infrastructure | Requires municipal gas lines | Self-contained, no grid needed |

| Portability | Not portable | Highly portable |

The numbers don't lie. Propane delivers more than double the energy.

That energy density difference is huge: one cubic foot of propane gives you a massive 2,516 BTUs, blowing past the 1,030 BTUs you get from the same amount of natural gas. For your kitchen, this means your fryers and griddles heat up faster and cook more efficiently, using less fuel. For high-volume spots, that's pure gold. You can find more data on US energy production over at Evaluate Energy.

Picture a busy Mexican food truck in East LA. Faster griddle recovery time between orders means more tacos served during the lunch rush. That’s a direct line from your fuel choice to your bottom line.

This kind of reliability is everything. A restaurant in a building can count on the city's gas supply, but a mobile vendor needs an energy source they can completely control. Propane gives you that confidence, ensuring you have a steady flame and predictable performance no matter where you set up for the day. At the end of the day, converting to propane is about giving your culinary vision the power and flexibility it needs to succeed anywhere in Los Angeles.

Your Essential Propane Conversion Toolkit

Jumping into a natural gas to propane conversion requires more than just good intentions; you need the right tools and parts lined up before you even think about turning a wrench. Getting your toolkit ready beforehand is the best way to sidestep frustrating delays and, more importantly, critical safety mistakes. This isn't just a generic shopping list—it's the specific restaurant equipment hardware that makes or breaks a successful conversion.

The absolute cornerstone of any conversion is the manufacturer-approved propane conversion kit. This part is non-negotiable. Every piece of equipment, from a high-output wok range in a San Gabriel Valley Chinese food kitchen to a compact griddle on a breakfast food truck, is a piece of precise engineering. Using a third-party or mismatched kit is asking for trouble, plain and simple. It can lead to terrible performance, damaged equipment, or even dangerous gas leaks.

Always start with the appliance's manual. Your model and serial number are the keys to ordering the exact kit designed for your machine. It’s the only way to avoid costly and hazardous guesswork.

Core Components You Cannot Skip

Beyond the kit itself, a few other pieces of hardware are crucial. Think of them as the supporting cast that ensures your main equipment runs flawlessly and safely. You’ll need to track these down to get the job done right.

- Adjustable Propane Regulator: Propane is stored under much higher pressure than natural gas. A dedicated propane regulator is absolutely essential to bring that pressure down to a safe, usable level for your appliances.

- High-Pressure Gas Hose: The standard hose you'd use for natural gas just isn't built for the higher pressures of propane. You have to invest in a quality, durable high-pressure gas hose made specifically for this. You can find a solid selection of commercial gas hoses at https://losangelesrestaurantequipment.com/products/gas-hose to see what fits your setup.

- Correctly Sized Orifices: The orifices, or jets, that control the gas flow are really the heart of the conversion. Because propane is denser and under higher pressure, it needs much smaller openings. Your kit should have these, but it's always a smart move to double-check their size against your manual.

Why Orifice Size Is Everything

Let's look at a real-world L.A. scenario. A food truck owner in DTLA snags a great deal on a used deep fryer that was set up for natural gas. To get it ready for mobile service, she has to do the conversion. That fryer’s massive burners, designed for rapid oil recovery to keep fries crispy, need a very specific orifice size to handle the intense heat required.

If she tried to use orifices from a kit meant for a small countertop range, the fryer would be starved of fuel. The result? Weak, low flames, painfully slow heating, and greasy, soggy food nobody wants. On the flip side, using orifices that are too big would create dangerously high, wild flames—a serious fire hazard. This logic applies everywhere, from the delicate simmer burner in a Japanese restaurant to the high-powered charbroiler in a K-BBQ spot.

For L.A. caterers and cafes upgrading to professional-grade Atosa under-counter units, switching to propane can be a game-changer. Propane packs a punch with 2,516 BTUs per cubic foot—more than double natural gas's 1,030 BTUs. That means hotter, faster performance for ranges and other gear without being tied to a gas line. This is a huge advantage for mobile operations, reflecting a broader trend where 46% of annual LPG use powers off-grid homes and businesses.

While you're putting your toolkit together, you might even consider a device like the Rapidox 1100 Methane Analyser to monitor for any remaining natural gas before and during the conversion, adding an extra layer of safety to the process.

The Appliance Conversion Process Explained

Once you have the right kit in hand, it’s time to get to work. The actual conversion from natural gas to propane is all about a few key mechanical tweaks that are absolutely critical for safety and performance. While the exact steps might differ slightly between a six-burner range and a commercial deep fryer, the core idea is the same for most restaurant equipment.

The entire process comes down to handling propane's unique character. Propane is delivered at a higher pressure and packs more energy, so your equipment needs smaller gas openings (orifices) and a different pressure setting to burn right. Nailing this is the difference between a clean, efficient flame and a dangerous, sooty disaster.

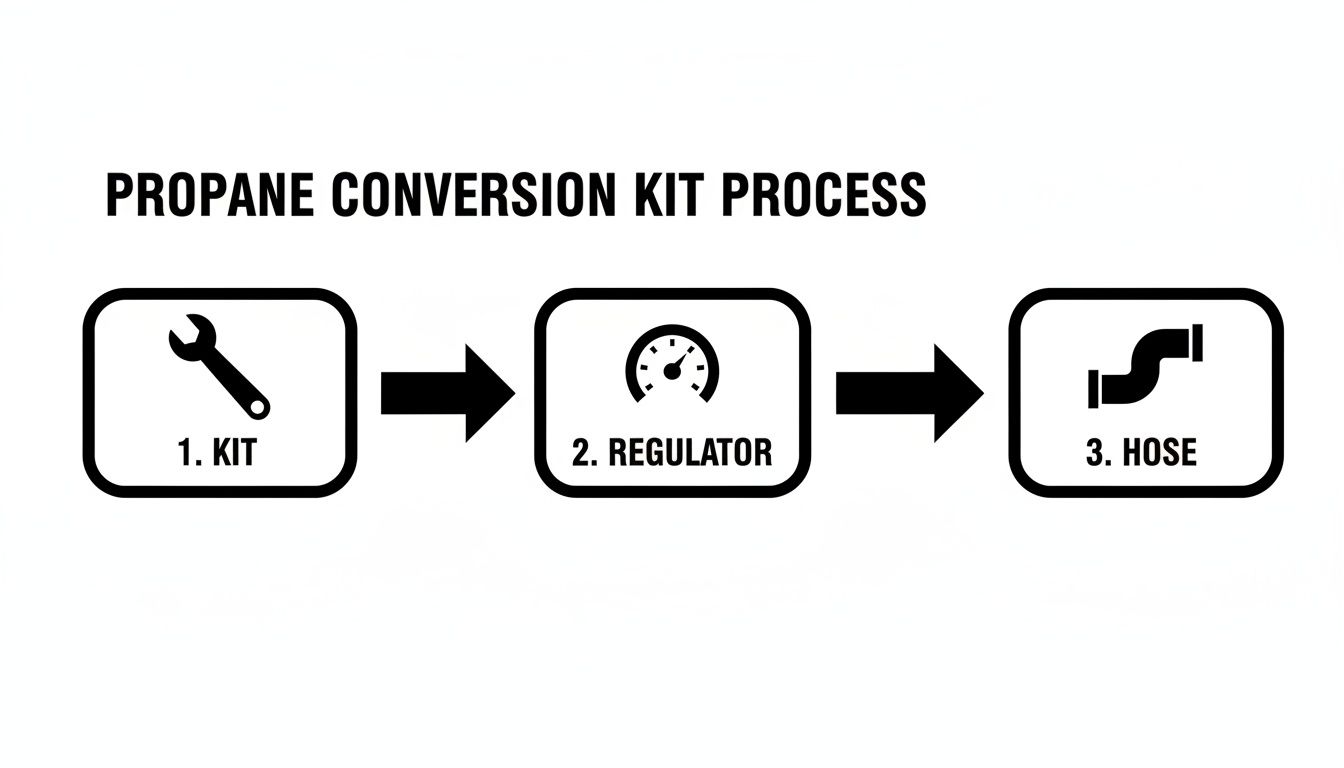

This little flowchart breaks down the three essential pieces you'll need for a clean conversion.

As you can see, the conversion kit, a specialized regulator, and a high-pressure hose all work together as a system to safely manage the switch.

Converting Your Multi-Burner Commercial Range

For any busy kitchen in LA, from a Thai food spot in Hollywood to a Mexican joint in Boyle Heights, the range is the undisputed workhorse. Converting it is usually the first and most important job. The goal is to swap out the natural gas orifices on each burner for the smaller propane ones from your kit.

First things first: always shut off the gas supply at the source. Then, you'll pull off the burner grates, heads, and anything else blocking your way to the orifices. These are typically small, brass fittings right where the gas flows into the burner tube. Grab the right-sized wrench or socket and carefully unscrew the old ones before installing the new.

A crucial step that’s easy to miss is adjusting the burner's air shutter. It’s a little movable plate at the base of the burner tube that controls the oxygen mix. Propane needs more air to burn cleanly, so you’ll need to open the shutter a bit until you see a steady, crisp blue flame with a small, darker blue inner cone.

Tackling Commercial Deep Fryers and Griddles

Switching over high-heat gear like deep fryers and flat-top griddles follows a similar process, but with safety dialed up to eleven because of the intense temperatures. The orifices on these units are usually bigger to deliver more BTUs, and you often have to dig a little deeper into the appliance’s guts to find them.

Here's a quick rundown for a typical commercial fryer:

- Disconnect and Cool Down: Make sure the fryer is unplugged, the gas is off, and the unit is completely cool to the touch.

- Find the Burner Assembly: You might need to remove a front or side panel to get to the main burner tubes and pilot light assembly.

- Swap the Orifices: Just like the range, replace the main burner orifices. And don't forget the pilot light orifice—it’s tiny but essential, and it needs to be swapped for its propane equivalent too.

- Adjust the Gas Regulator: Your appliance's internal regulator will have an adjustment cap. You have to flip it from the "NAT" (natural gas) setting to "LP" (liquid propane). This is a non-negotiable step for handling propane's higher pressure.

The perfect flame is your best sign of a job well done. If you see a lazy, yellow, or sooty flame, your air-to-fuel mix is off. That's not just inefficient—it produces carbon monoxide. You need to adjust the air shutter immediately.

Handling Convection Ovens and Charbroilers

Convection ovens and charbroilers, especially the kind you see in Korean BBQ restaurants that need that intense, direct heat, require careful calibration. The process still involves changing the main orifices and adjusting the regulator, but you might also need to tweak the thermostat calibration to keep your cooking temperatures accurate.

For a charbroiler, getting an even flame across all the burners is everything. It’s the key to avoiding hot spots that can torch expensive cuts of meat. After you’ve installed the new orifices, light each burner and check the flame height and color. You’ll probably need to make minor adjustments to individual air shutters until you have a uniform wall of blue flame. This kind of detail work is what separates the pros. Having a clear plan from the get-go, like a solid commercial kitchen equipment checklist, can make all the difference.

The Final Safety Check: Leak Testing

After you’ve converted any gas appliance, a thorough leak test isn't just a suggestion—it's an absolute must. You can whip up a leak detection solution easily with a 50/50 mix of dish soap and water in a spray bottle.

With the propane tank connected and the valve open, spray down every connection point you touched:

- The connection at the propane tank regulator.

- The hose connections at both the regulator and the appliance.

- The new orifices and any fittings around the pilot light.

Now, watch closely for bubbles. Even a tiny stream of bubbles means you have a gas leak. You have to fix it immediately by tightening the connection or reapplying pipe dope and testing again. Don’t even think about operating the equipment until all leaks are gone. This final check is your ultimate safety net, ensuring your kitchen is ready for safe, high-performance service.

Navigating Los Angeles Safety Codes and Permits

Switching your kitchen equipment from natural gas to propane in Los Angeles is more than a simple mechanical swap. To keep your operation legal and safe, you have to play by the local rules set by city and county authorities. This isn't just red tape—it's about protecting your staff, your customers, and your business from some very real risks.

Trying to sidestep these regulations can get you slapped with heavy fines, a forced shutdown, or worse, lead to a tragic accident. For any LA restaurant owner, and especially for Los Angeles food truck operators, getting this right is just part of running a professional kitchen.

When You Need a Permit from LADBS

For most permanent installations, the Los Angeles Department of Building and Safety (LADBS) is the agency you’ll be dealing with. If your conversion is part of a bigger renovation or you’re modifying the building’s fixed gas piping system, you can bet a permit is required.

This usually applies to brick-and-mortar restaurants, whether it’s a Japanese spot in Little Tokyo or a busy Chinese restaurant in the SGV. Anytime you touch the core infrastructure that feeds fuel to your appliances, LADBS needs to sign off on it to ensure everything is up to code.

Los Angeles food trucks are a different story. You won’t need a building permit for the vehicle itself, but you'll have to satisfy other agencies, most notably the LA County Department of Public Health and the Fire Department.

Why a Licensed Technician Is Non-Negotiable

Look, I get the DIY spirit, but converting from natural gas to propane is one of those jobs you absolutely leave to a licensed pro. The consequences of a botched job—gas leaks, carbon monoxide poisoning, or fires—are just too severe.

A licensed gas technician does more than just install parts. They verify that the entire system, from the tank regulator all the way to the burner flame, is working safely and efficiently. Think of their expertise as the best insurance policy you can buy.

When you're trying to wrap your head around local rules, understanding the necessary LPG gas safety certificate requirements is crucial. A professional ensures your setup is 100% compliant and provides the paperwork that health and fire inspectors will want to see.

LA Fire Department Rules for Propane Storage

For any kitchen using propane, the Los Angeles Fire Department (LAFD) has strict rules for storing and handling tanks, especially for mobile setups like food trucks and catering vans. These regulations are all about preventing accidents in our crowded city.

Here are a few key LAFD requirements you’ll likely encounter:

- Secure Mounting: Tanks have to be securely fastened to the vehicle or kept in a purpose-built, ventilated compartment. No exceptions.

- Proper Ventilation: If your tanks are in an enclosure, it needs proper ventilation so gas can't build up.

- Distance from Ignition Sources: Keep tanks a safe distance from open flames, electrical outlets, or anything else that could spark a fire.

- Regular Inspections: Tanks need to be checked regularly for rust, dents, or valve damage. They also need to be recertified periodically.

As LA’s foodservice pros deal with the unpredictability of natural gas, the boom in global propane is making a strong case for switching. U.S. propane exports hit a record 1.8 million barrels per day in 2024, an industry surge driven by natural gas processing, which is where 76% of propane comes from. This has created a steady, affordable supply. For a restaurant manager, that means propane's higher energy density (2,516 BTUs per cubic foot vs. natural gas's 1,030) can fuel bigger outputs from smaller tanks—a huge plus for mobile kitchens.

Essential Post-Conversion Safety Checks

Once a professional has handled the conversion, there are a few ongoing checks you should be doing yourself to keep things safe. These simple visual inspections can help you catch a problem before it becomes a disaster.

First, always check the flame color. A properly adjusted propane appliance should have a steady, crisp blue flame with a slightly darker blue inner cone. If you see yellow or orange flames, or you notice soot building up, that’s a red flag for incomplete combustion, which can create deadly carbon monoxide.

Second, remember how propane works. It's heavier than air, so if there's a leak, the gas will sink and pool in low spots. Make sure your kitchen or food truck has good low-level ventilation to stop this from happening. Following these steps and sticking to the local codes is the only way to make sure your conversion is both successful and safe.

Budgeting for Costs and Performance Impacts

Deciding to convert from natural gas to propane isn't just a technical puzzle; it's a move that impacts your wallet and your kitchen's workflow. For any Los Angeles restaurant owner, getting a handle on the real-world budget and performance changes is absolutely essential before you pull the trigger.

The total price tag is more than what you pay for a conversion kit. You need to think about a few key expenses to build a realistic budget. Sorting these costs out upfront helps you dodge unpleasant surprises and makes sure you have the cash ready for a smooth switch.

Breaking Down the Conversion Costs

The final bill is going to be a mix of parts, labor, and maybe some city fees. For a single piece of commercial restaurant equipment, you can expect a typical conversion to run anywhere from $150 to over $500. This range really depends on how complex the appliance is and the going rate for technicians in the area.

Here’s where your money is going:

- Conversion Kits: The kits themselves are usually pretty affordable, often landing somewhere between $25 and $100. The price shifts based on the brand and model of your equipment.

- Professional Installation: This is the biggest piece of the pie. Hiring a licensed gas technician in Los Angeles can set you back $100 to $400 or more. For safety and to stay on the right side of the law, this part isn't optional.

- Permitting Fees: If your project needs a permit from the LADBS, you'll have to add that to your costs. These fees can vary, but they're a necessary step for a lot of permanent installations.

Covering these upfront costs can be tough, especially if you're launching a food truck or expanding your restaurant. To make it more manageable, looking into options like Los Angeles restaurant equipment financing can help you get the gear you need converted and running without draining your cash reserves.

Will Conversion Void My Warranty?

This is a huge question, and every restaurant owner needs to ask it. The answer is almost always hiding in the fine print of your manufacturer's warranty. Most manufacturers will only keep the warranty valid if the conversion is done with their official, brand-specific kit and installed by a certified pro.

Trying to save a buck with a third-party kit or doing it yourself is the fastest way to kill your warranty. Before you start, find the warranty papers for your Atosa range or fryer. If you can't find them, a quick call to the manufacturer's support line will give you a clear answer and protect your investment.

Always check your equipment's warranty terms before you even think about starting a conversion. A voided warranty on a brand new commercial oven could turn a small project into a massive financial headache.

Setting Performance Expectations

One of the best things about switching to propane is its energy punch. Propane packs 2,516 BTUs per cubic foot, blowing past natural gas’s 1,030 BTUs. In a busy kitchen, this often means your fryers and griddles heat up faster and get back to temperature quicker after you drop in a batch of cold food.

But with great power comes the need for great precision. After the conversion, your equipment needs to be calibrated perfectly to hold consistent cooking temperatures. This is especially critical for delicate jobs, like simmering broth for a Japanese ramen spot, or for the high-heat blasts needed for a wok in a Thai kitchen. A good technician will dial in the regulator and air shutters to give you that steady, controllable blue flame your chefs need to produce consistent quality.

Common Questions on Propane Conversion

Running a busy Los Angeles restaurant or food truck means you need answers, and you need them fast. When it comes to switching from natural gas to propane, a lot of questions pop up. We’ve put together the most common ones we hear to give you the straightforward info you need.

Yes, most of the time you can. Modern manufacturers like Atosa know that Los Angeles food trucks and pop-ups need flexibility. They design their ranges, fryers, and ovens with conversion in mind and usually offer official kits. But—and this is a big but—it’s not a universal guarantee. Always, always check the manual for your specific model or call the manufacturer directly to confirm it’s possible before you spend a dime.

Is Converting to Propane a DIY Job?

It might look simple on a YouTube video, but this is one job you absolutely must leave to a licensed professional. Propane is a different beast than natural gas; it operates at a much higher pressure. One wrong move, like using the wrong orifice or forgetting to adjust the regulator, can lead to dangerous gas leaks, inefficient flames, or even a fire.

For the safety of your staff, your customers, and your business, hiring a qualified gas technician is non-negotiable. They have the right tools and the experience to do the job safely, test for any leaks, and get your equipment perfectly calibrated.

A professional conversion isn't just a good idea. It's often required to keep your warranty from being voided and to stay in line with Los Angeles safety codes. Think of it as an investment in keeping your business safe and sound.

How Does Propane Affect Cooking Performance?

A lot of chefs actually end up preferring propane once their equipment is properly dialed in. Propane has a higher energy density, packing in more than twice the BTUs of natural gas for the same volume. You'll notice this right away with faster preheat times and quicker temperature recovery—a huge plus for a fryer during the lunch rush or a range on a slammed Saturday night.

The secret is in the conversion. A good technician will adjust the air-to-fuel ratio to give you that perfect, steady blue flame. If it’s not calibrated right, you’ll end up with sooty, weak yellow flames that don't heat evenly and can ruin your food.

What's the Difference Between a Propane and Natural Gas Regulator?

This is a critical safety point: they are not interchangeable. Natural gas flows from a city line at a very low, consistent pressure. Propane, on the other hand, is stored as a liquid under high pressure inside a tank. A propane regulator's job is to knock that pressure way down to a level your appliance can handle safely.

Your conversion will involve two separate regulator adjustments:

- The Tank Regulator: This is the first one, attached directly to the propane tank itself.

- The Appliance Regulator: Most commercial appliances have their own internal regulator that needs to be physically switched from its "NAT" (natural gas) setting to "LP" (liquid propane).

Trying to use a natural gas regulator with a propane tank would be incredibly dangerous, as it simply isn’t built to handle that initial high pressure.

At Los Angeles Restaurant Equipment, we get the unique pressures of the LA food scene. From high-performance Atosa ranges perfect for your new food truck to the commercial refrigerators that keep your ingredients fresh, we have the gear you need to succeed. Explore our full catalog and find the right restaurant equipment for your kitchen at https://losangelesrestaurantequipment.com.