Ice machine is not making ice: Quick fixes for fast results

Share

When your ice machine is not making ice, it's often a simple fix. Before you start thinking about a major breakdown, take a moment to check the basics: power, water, and the machine's settings.

Your First 5 Minutes: What To Check Immediately

There’s a special kind of dread that hits when you hear the deafening silence of a commercial ice machine during a chaotic Los Angeles dinner rush. Whether you’re running a busy Thai kitchen in Hollywood or a bustling taco truck in the Arts District, an unexpected ice shortage can bring service to a grinding halt.

Before you panic and call for an expensive emergency repair, just take a deep breath. More often than not, the problem is something you can fix yourself in under five minutes—no tools required. These first checks are the low-hanging fruit of troubleshooting. They seem obvious, but in the heat of the moment, they're the first things we forget.

The Power and Water Basics

Let's start with the absolute essentials. Is the machine securely plugged into the wall? It's surprisingly common for cleaning crews or other staff to accidentally knock the plug loose.

Next, find your electrical panel. A tripped breaker is a frequent offender, especially in older Los Angeles buildings or kitchens where multiple pieces of heavy-duty restaurant equipment, like commercial refrigerators and freezers, share a circuit. A quick flip of the switch might be all it takes to get things running again.

If the machine has power—you can see lights on or hear a fan humming—but nothing's happening, your next stop is the water supply. Trace the water line from the wall back to the machine and make sure the valve is turned completely open. Sometimes, it gets bumped and partially closed, restricting the flow just enough to stop ice production.

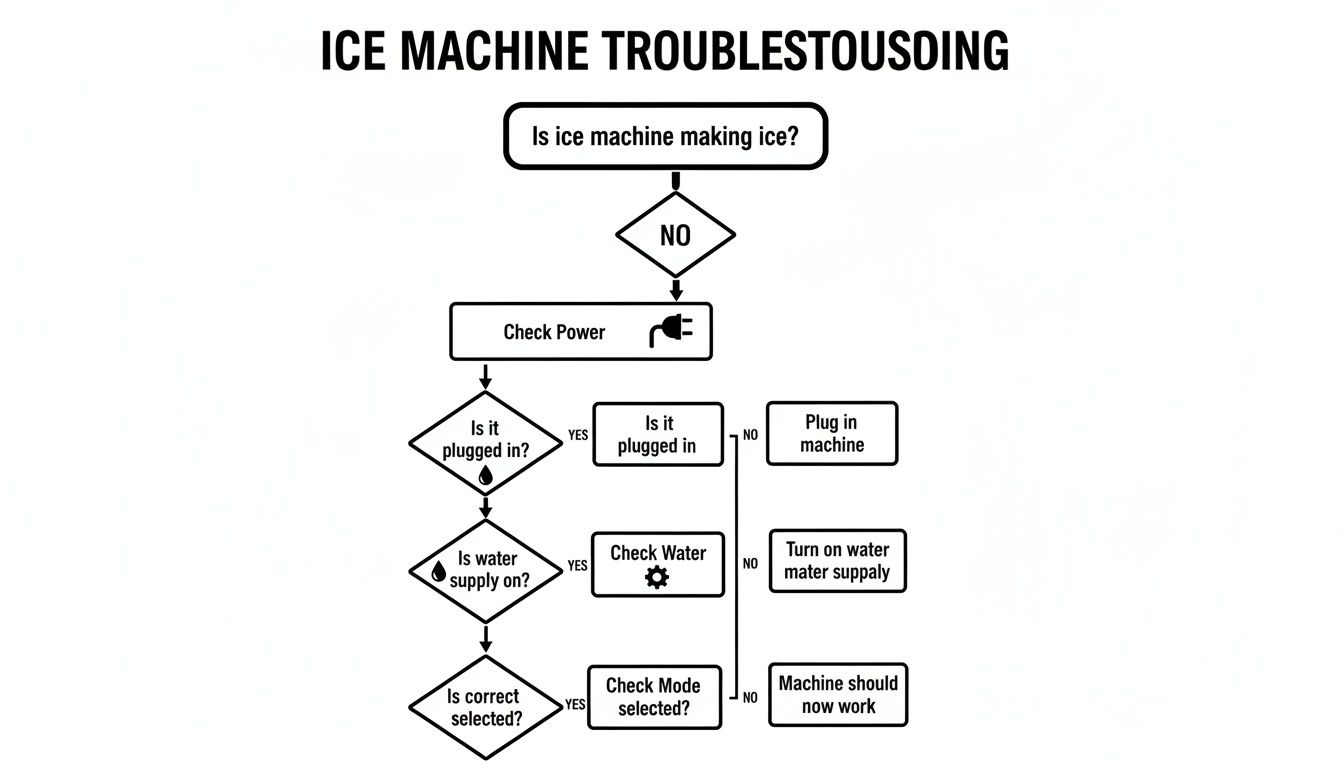

This simple flow helps visualize those first few steps. Always confirm the fundamentals—power and water—before digging any deeper.

Confirming the Machine's Mode

Another common culprit is the machine’s operational setting. Many commercial ice makers have a "Clean" or "Wash" cycle. If this mode gets accidentally activated, the machine will stop producing ice until the cycle finishes or you switch it back to "Ice" mode.

Take a quick look at the control panel. Are there any indicator lights suggesting it's in a cleaning or diagnostic mode?

Pro Tip: We once got a call from a busy Koreatown BBQ spot where a brand-new machine had stopped making ice. The cause? A staff member had unknowingly flipped the main toggle switch to 'off' while wiping down the exterior. Always, always check the power switch on the unit itself.

Here's a quick table your team can use to run through these initial checks systematically.

Quick Diagnostic Checklist

| Symptom | Potential Cause | Immediate Action |

|---|---|---|

| Machine is completely silent, no lights. | No power. | Check if the plug is secure. Check the circuit breaker. Check the main power switch on the unit. |

| Lights/fan are on, but no ice cycle starts. | Water supply issue. | Find the water inlet valve behind the machine and ensure it is fully open. |

| Lights are on, you hear water, but no ice. | Incorrect operating mode. | Look at the control panel for "Clean," "Wash," or "Service" lights. Switch it back to "Ice" mode. |

Running through this quick checklist can often solve the problem in minutes, getting you back to serving customers without the stress or cost of a service call.

Why Most Ice Machine Breakdowns Are Avoidable

It's tempting to blame a broken ice machine on bad luck, especially when you're in the middle of a brutal Los Angeles heatwave. But here’s the reality I’ve seen time and time again: most of these "sudden" failures aren't sudden at all. They’re the final, predictable outcome of months of quiet neglect.

For a high-volume Japanese restaurant in Little Tokyo or a slammed food truck in Thai Town serving authentic Thai food, an equipment emergency is more than just a headache. It's a direct hit to your sales. Every minute you can't serve a drink with ice is a minute you're losing money on your most profitable items.

The Hidden Costs of Neglect

The most common issues are the ones you don't see—at first. Things like mineral scale from Southern California’s hard water, clogged filters, and condenser coils caked in dust don't just stop ice production overnight. Long before that happens, they force the machine to struggle, working harder and running longer for the same result.

That extra strain shows up on your utility bills. A struggling machine can use way more electricity, quietly eating into your profits. It’s a lot like how a dirty filter in a commercial refrigerator or freezer forces the compressor to run nonstop. This is a common issue with all types of restaurant equipment.

The numbers are pretty stark. Industry data shows that a whopping 70% of ice machine service calls are completely preventable with just basic, routine care. The average bill for those avoidable repairs? A painful $708. For a major failure like a burnt-out compressor, it can easily climb past $2,000.

From Minor Annoyance to Major Failure

What begins as a small problem, like your ice looking a bit cloudy, can quickly snowball into a complete shutdown. Think about these common scenarios I see in the field:

- Scale Buildup: Hard water minerals create a rock-like layer on the evaporator plate. This acts like insulation, making it incredibly difficult for water to freeze and eventually stopping the harvest cycle altogether.

- Dirty Condenser Coils: The condenser is your machine's radiator. When it gets coated in kitchen grease and dust, it can't release heat properly. This leads to overheating and, eventually, a fried compressor.

- Clogged Filters: A choked-off water or air filter is like trying to run a marathon while breathing through a straw. The machine is starved for water or can't get enough air, putting immense stress on every single component.

The key is to understand that a dead ice machine is just the symptom, not the disease. Once you recognize the real financial impact of downtime and the slow-burn damage caused by neglect, you can shift from reacting to problems to preventing them. It’s the single best investment you can make for your restaurant’s health.

Solving Water Supply And Filtration Problems

If your machine is getting power but the ice tray is completely dry, your next stop should be the water supply. In a busy commercial kitchen, especially somewhere like Los Angeles with its notoriously mineral-heavy water, these issues are hands-down the most common reason an ice machine is not making ice.

Hard water is the absolute nemesis of any commercial ice machine. Over time, those dissolved minerals—mostly calcium and magnesium—build up into a chalky substance we call scale. This gunk clogs up the tiny pathways in the water inlet valve, basically choking off the water your machine needs to make ice. A valve that’s supposed to be fully open can get narrowed down to a pinhole, killing your water pressure and bringing ice production to a dead halt.

Inspecting Your Water Inlet And Filter

Your first move should be a quick visual check. Follow the water line back to the machine and find the water inlet valve, which is the little part that actually lets water into the unit. If you see any white, crusty stuff around the connections, that’s a dead giveaway for mineral buildup.

The next thing to check is your water filter. A clogged or old filter is like putting a dam in your water line. It doesn’t just slow down the flow; it stops trapping the very minerals that are causing all the destructive scale in the first place.

- Check the Filter Date: Most commercial filters have a date written on them. If you’re running a high-volume spot in Los Angeles, you need to be swapping this out every 3-6 months, no excuses.

- Observe the Water Flow: If you can, try disconnecting the line right after the filter and letting it run into a bucket. If the flow is weak or just sputters out, you’ve found a blockage. The problem is either the filter or the line itself.

Getting a handle on water supply and filtration problems really comes down to having the right system in place. For a deeper dive, check out this guide on choosing the ultimate water filtration system for a commercial space.

The Impact of Scale Buildup

What if some water is getting through, but the machine is slow or the cubes look small and cloudy? That’s a classic sign that scale is starting to coat the evaporator plate. That’s the ice-cold grid where the water freezes into cubes. Scale acts like an insulator, making the refrigeration system work way harder just to get cold enough.

The numbers don't lie: professionally maintained ice machines have 80% fewer emergency breakdowns compared to neglected ones. One study pinpointed scale buildup as the #1 culprit, showing it forced machines to work overtime, jacking up energy costs while tanking production. Just descaling the units boosted their output by 20-30% in most cases.

Letting this buildup go is just asking for trouble. That constant strain will eventually burn out your compressor, and that’s a repair bill you don’t want to see. Regular professional descaling isn’t just about cleaning—it's a critical investment that will massively extend your machine's life and keep it pumping out ice at full capacity, so you never have to worry during a dinner rush.

Diagnosing Common Mechanical And Electrical Issues

So, the simple power and water checks didn't do the trick. Now it’s time to get a little more hands-on and start listening to what the machine is trying to tell you. When an ice machine is not making ice due to a mechanical or electrical fault, it almost always gives off clues. You don’t need an engineering degree to spot them, just a few minutes of careful observation in your L.A. restaurant kitchen.

Think of this as a quick wellness check for your most vital equipment. We're going to pay close attention to the sounds and temperatures of key components. The goal here is to gather specific information that can help you—or a technician—figure out the problem fast.

Listening to Your Machine's Core Components

The refrigeration system, mainly the compressor and condenser, is the heart of your ice machine. These are the parts doing the heavy lifting to create the cold needed to freeze water.

First, find the condenser unit. It looks a lot like a car's radiator and will have a fan. Is that fan spinning? If so, great. That’s a good sign the machine is at least trying to cool itself down. Now, lean in and listen. You should hear a low, steady hum from the compressor, which is usually a black, tank-like component sitting nearby.

-

If the fan spins but the compressor is dead silent: This almost always points to an electrical problem. The compressor isn't getting the signal or the juice to turn on. The culprit could be anything from a bad thermostat to a failed starting component.

-

If both the fan and compressor are running, but still no ice: Let the machine run for a good 20-30 minutes. If the evaporator plate (the metal grid where ice forms) isn't even getting frosty, you're probably looking at a refrigerant issue. That's not a DIY fix; you'll need a certified technician for that one.

A lot of electrical gremlins in these machines can be traced back to the switching mechanisms, like electrical contactors, which act as the gatekeepers for power to the major components. A fried contactor can easily stop a compressor from ever kicking on.

Observing a Harvest Cycle

The "harvest cycle" is the grand finale—when the machine releases its finished ice into the bin. Just watching this one process can tell you exactly where things are going wrong.

Once the ice is frozen solid, the machine is supposed to briefly warm the evaporator plate just enough for the cubes to let go and slide off. If your machine makes a perfect sheet of ice but it just sits there, the harvest cycle is failing. This is often caused by a bad solenoid or a problem with the ice thickness sensor.

A huge issue we see in hot Los Angeles kitchens is the room temperature itself. An ice machine crammed into a 95°F kitchen is working overtime just to stay cool. If the unit feels hot and there's less than six inches of breathing room around the vents, it’s probably overheating. Poor ventilation can look and feel a lot like a serious mechanical failure.

Understanding Thermostat and Sensor Issues

Your ice machine is full of sensors and relies on a thermostat to run its cycles correctly. A faulty thermostat might never tell the compressor to turn on, or it might not realize the water is cold enough to freeze.

Take a look at the machine's display, if it has one. Check for any error codes. These codes are a technician's best friend and can point you directly to a specific malfunctioning sensor or control board.

Knowing these details before you call for service can save a technician a ton of diagnostic time, which saves you money. Being able to say, "The condenser fan is running but the compressor is silent," is way more useful than just, "It's broken."

Creating A Proactive Ice Machine Maintenance Plan

The absolute best way to handle an ice machine not making ice is to stop the problem before it ever starts. Instead of panicking during a dinner rush, a solid maintenance plan turns equipment care from a chaotic fire drill into a simple, predictable routine. For any busy Los Angeles restaurant, this simple shift saves money, cuts down on stress, and ultimately protects your bottom line.

A consistent schedule is the secret sauce. By breaking tasks into daily, weekly, and monthly checklists, maintenance becomes a manageable part of the day for your whole team. This isn't about adding hours of work; it's about building in small, five-minute habits that add up to a huge impact over time, keeping your machine humming along.

Building Your Maintenance Checklist

A good plan doesn't need to be some complicated binder. Just start with the basics and make sure everyone knows who is responsible for what, whether you're running a bustling downtown Chinese spot or a popular Koreatown BBQ joint.

- Daily Tasks (End of Shift): Have your closing crew give the machine's exterior and the scoop a quick wipe-down. This simple step prevents grime from building up and keeps things looking professional.

- Weekly Tasks (Slow Day): Once a week, take a few minutes for the ice bin. Pull all the ice out, clean the inside with a food-safe sanitizer, and wipe it completely dry. This is your best defense against slime and mold.

- Monthly Tasks (First of Month): A manager should pull out and inspect the air filter. In a hot L.A. kitchen, a clogged filter is one of the top reasons for overheating. They should also take a look at the water filter and jot down its next replacement date.

Knowing When to Call a Professional

While your staff can easily handle the day-to-day cleaning, it’s vital to know where to draw the line. Trying to tackle a complex repair without the right training is not only dangerous, but it can also void your warranty and often just make the problem worse.

Critical Safety Warning: Never, ever try to work on the compressor or touch the refrigerant lines yourself. These systems are under extreme pressure and contain chemicals that require a certified technician with specialized tools to handle safely.

Set a clear red line for your team. If the fix involves taking off major panels, messing with any electrical wiring beyond the wall plug, or anything inside the sealed refrigeration system, it's time to stop. Your smartest move is to call an authorized service technician. This protects your equipment and ensures the job gets done right.

And if you find yourself dealing with the same issues over and over, it might be a sign that your unit is on its last legs. When that time comes, you can explore reliable new commercial ice makers that can keep up with your kitchen's demands.

Common Questions From L.A. Restaurant Owners

In our line of work, dealing with restaurants and food trucks all over Los Angeles, we tend to hear the same questions over and over. When an ice machine is not making ice, it causes the same level of panic whether you're running a high-end sushi spot in Beverly Hills or a taco truck in East L.A. Here are the answers to the most common issues we see from busy owners and managers.

Why Is My Machine Making Small Or Cloudy Ice?

Nine times out of ten, this is a water problem—a constant battle with the notoriously hard water here in L.A. If you're getting small or hollow cubes, that's a classic sign of low water flow. The culprit could be anything from a clogged filter to a water inlet valve that's scaled up.

Cloudy, soft ice, on the other hand, is a dead giveaway for high mineral content in your water supply. For most L.A. businesses, from Mexican restaurants to Japanese kitchens, the best defense is a good offense: replace your water filter every 3-6 months and schedule a professional descaling service twice a year. This simple routine ensures clear, solid ice and helps you avoid much bigger, more expensive problems down the road.

How Often Should I Have My Commercial Ice Machine Cleaned?

You should be getting a professional deep cleaning and sanitizing at least every six months, especially for a busy restaurant or bar. This isn't just a wipe-down; this service gets deep inside the machine to remove the internal scale, slime, and mold that your daily cleaning can't touch.

In between those professional visits, your staff should be sanitizing the ice bin weekly and at least checking the air and water filters monthly. Think of it less as a chore and more as insurance—it’s about preventing the costly clogs and component failures that all that buildup eventually causes. For a complete look at all your kitchen maintenance duties, our commercial kitchen equipment checklist is a great resource.

Does The Heat In My Kitchen Affect The Ice Machine?

It absolutely does. An ice machine's ability to produce ice is directly tied to the air temperature around it. Once your kitchen gets above 90°F, that machine has to work exponentially harder just to cool itself down. This drastically cuts your ice production and puts a massive strain on the compressor.

Make sure there's always at least 6 inches of clearance around the machine's air vents so it can breathe. A hot, cramped kitchen is one of the leading causes of premature equipment failure, especially in the demanding Los Angeles climate.

We once walked into a Chinese restaurant where the ice machine was shoved right up against a deep fryer. Their ice production had been cut in half. The fix? We just moved the unit to a cooler wall with better airflow. Problem solved, no costly repair needed.

My Ice Machine Is Leaking Water, What Should I Do?

First, check for the simplest cause: a clogged drain line in the ice bin. A little bit of food debris or slime is all it takes to block that drain, causing water to back up and spill out onto your floor.

If the drain looks clear, the leak might be coming from a cracked water line, a bad inlet valve, or a problem with the harvest cycle. To prevent serious water damage, shut off the water supply to the machine immediately and call a qualified technician. Leaks often point to an internal part that has failed, and that's something you want a professional to diagnose and fix correctly.

When repairs start costing more than they're worth, Los Angeles Restaurant Equipment is here to help you find a reliable, high-performance replacement that can handle the demands of your business. Browse our full collection of commercial kitchen equipment and get back to serving your customers without interruption. https://losangelesrestaurantequipment.com