Commercial Refrigerator Installation: A Practical Guide for LA Restaurants

Share

Getting a commercial refrigerator installed properly is about way more than just finding an outlet and plugging it in. It’s a full-on process involving site assessment, checking your utilities, and strategic placement to make sure the unit runs at its best.

Nailing these first steps is what separates a smooth-running kitchen from one plagued by costly equipment headaches down the line. For any busy L.A. restaurant, from a Japanese sushi bar to a Thai food kitchen, this prep work is the bedrock of an efficient operation.

Setting the Stage for a Flawless Installation

Before that shiny new refrigerator even shows up on the delivery truck, a little legwork can save you from a massive installation-day nightmare. Think of it as the mise en place for your restaurant equipment—an absolutely critical step for any Los Angeles kitchen, whether you're running a high-volume K-Town BBQ joint or a tiny Thai food truck in Silver Lake. Getting the site ready is how you protect a major investment.

The whole thing starts with a tape measure and a good, hard look at your space. You need to measure every single doorway, hallway, and tight corner along the delivery path. It’s a rookie mistake to just assume the unit will fit, only to have it get wedged in a corridor. That's a surefire way to cause delays, damage your new equipment, and rack up extra labor costs.

Ensuring a Solid and Safe Foundation

Once you've mapped out a clear path, turn your attention to where the refrigerator will actually live. The floor has to be strong enough to handle its considerable weight, especially when it's packed to the gills with inventory. A floor that sags or is uneven can warp the unit's frame, putting stress on the whole system and leading to premature compressor failure.

Beyond just being level, airflow is completely non-negotiable. Shoving a refrigerator right next to a heat source—like your wok range in a Chinese restaurant or a deep fryer—is a recipe for disaster. It forces the compressor to work overtime just to keep cool, which burns through electricity and drastically shortens its lifespan. You have to leave enough clearance on all sides for proper ventilation so heat can escape.

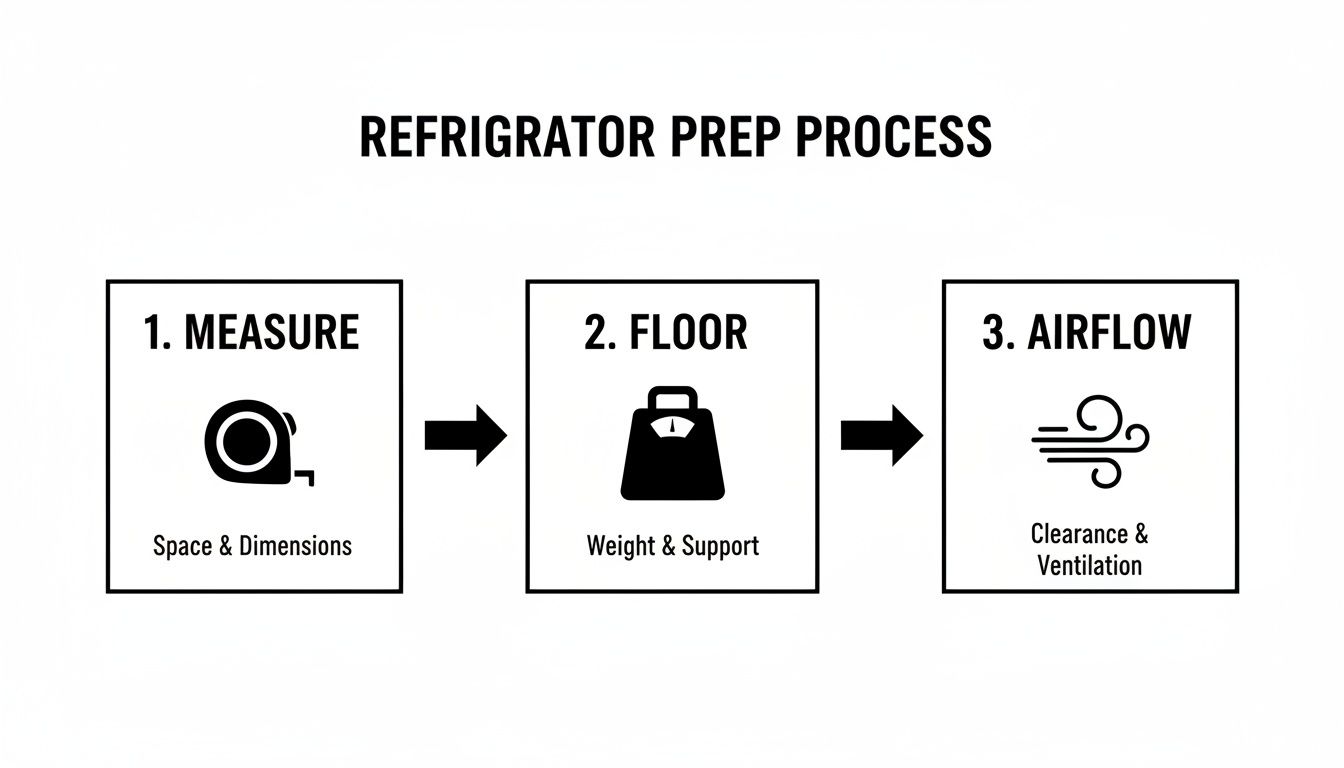

This simple breakdown hits the three main prep points.

Thinking about it as Measure, Floor, and Airflow really drives home how these basic checks are the foundation of a successful installation.

Utility and Safety Checks

Finally, it's time to check your hookups. Most commercial refrigerators are power-hungry and need a dedicated electrical circuit to avoid tripping breakers every time the compressor kicks on. Look at the unit’s spec sheet and make sure you have the right kind of outlet ready and waiting.

And if your model has an ice maker or uses a condensate evaporator, you'll also need to plan for a water line and a proper drainage setup.

The global demand for commercial refrigerators is booming, and North America is leading the charge. In a foodservice capital like Los Angeles, where food trucks and diverse cuisines are part of the city's DNA, getting the setup right is key for both efficiency and compliance. A correct installation alone can slash energy use by up to 20-30%—a huge saving when you think about how high operational costs can get.

Before any heavy equipment shows up, you have to get your team on the same page about safety. Take a few minutes to review these heavy equipment installation safety tips to make sure the whole process is safe and secure.

Treating these prep steps seriously is a fundamental part of a smart commercial kitchen layout design and sets your restaurant on the path to long-term success.

Navigating Los Angeles Permits and Health Department Rules

Here in Los Angeles, getting a commercial refrigerator installed correctly is about more than just finding a spot and plugging it in. You’ve got to play by the rules set by the LA County Department of Public Health. Mess this up, and you’re looking at failed inspections, painful fines, and a grand opening that’s dead in the water.

Before a single tool comes out, you need to think like a health inspector. They aren’t just sticking a thermometer inside to check the temp; their first look will be for the right certification. Your unit absolutely must have an NSF (National Sanitation Foundation) sticker on it. That little mark is their proof that it’s built for a commercial kitchen—safe to use and easy to clean.

Key Compliance Checks for LA Kitchens

Beyond that NSF seal, the inspector is going to be scrutinizing exactly where and how you installed the unit. You can’t just shove it against the wall. They’ll get out a tape measure and check for proper clearance, which is usually at least six inches all around. This isn't just a random rule; it’s to make sure your staff can get back there and clean, preventing a buildup of grease and grime that inspectors hate to see.

Then there are the utilities. If you need a new dedicated circuit to handle the power load or have to run a new drain line for condensation, you can't just have your handyman do it. You are required to bring in licensed pros.

- Licensed Electrician: A must for any new wiring or outlet installations. They’ll ensure everything is up to LA building codes.

- Licensed Plumber: Essential for connecting drain lines or hooking up water supplies for units with ice makers.

Trying to cut corners here with unlicensed work is a classic rookie mistake. An inspector can spot it from a mile away, and they’ll shut you down until you rip it out and have a certified tradesperson do it right. You’ll end up paying twice.

Special Considerations for Food Trucks

For anyone joining LA's legendary food truck scene, there’s an extra layer of rules. Of course, you need an NSF-certified fridge, but it also has to be bolted securely to the truck’s frame. The last thing an inspector wants to see is a multi-hundred-pound refrigerator that could slide around during a hard stop. It’s a huge safety risk and an automatic fail.

Ventilation is another big one for mobile kitchens. Inspectors know how hot it gets inside a truck, so they’ll check that your fridge has enough breathing room to vent heat properly. A poorly ventilated unit will struggle to stay cool, putting your food in the danger zone.

Make sure you have all your paperwork ready for inspection day. That means having the refrigerator's spec sheet (clearly showing the NSF mark) and copies of the invoices from the licensed electrician or plumber you hired. Being organized and prepared shows the inspector you’re serious, helping get your Korean BBQ taco truck or Japanese curry spot on the road that much faster.

Deciding Between Professional and DIY Installation

So, you’ve wrestled with the permits and your shiny new commercial refrigerator or freezer has finally arrived. Now you’re at a crossroads that every Los Angeles restaurant owner faces: do you call in the pros for the installation, or try to handle it yourself? The urge to save some cash with a DIY job is always strong, especially when you’re watching every dollar.

But let me tell you, this is one area where "saving money" can end up costing you a fortune. A single, seemingly small mistake during installation can snowball into a complete disaster. Imagine your team doesn't level the unit perfectly—that slight imbalance puts a huge strain on the compressor, guaranteeing it will burn out way before its time. Or what about the wiring? One wrong connection isn't just a fire hazard; it's a surefire way to instantly void your manufacturer's warranty. Suddenly, that "cheaper" option doesn't seem so cheap anymore.

When Professional Installation Is a No-Brainer

For the vast majority of LA restaurants, whether it’s a packed ramen spot in Sawtelle or a sprawling Mexican restaurant in East LA, hiring a certified technician is simply the smarter business move. These folks do this day in and day out. They know the quirks of different models and are wizards at maneuvering heavy restaurant equipment into the tight, awkward spaces that define so many commercial kitchens.

More than that, a professional install is an insurance policy for your investment. A pro makes sure every connection is solid, the unit is perfectly balanced, and the system is running at peak efficiency from the moment it's turned on. They're also insured, so if anything goes sideways during the setup, the liability isn't on you. That kind of peace of mind lets you get back to what you do best—running your business.

For most of us in the industry, it really comes down to risk versus reward. The cost of a professional installation is a known, predictable expense. The potential cost of a botched DIY job—from wrecked equipment and voided warranties to days of lost business—is a massive, unpredictable gamble.

The decision between hiring a professional and doing it yourself is a critical one. To help you weigh the options, here’s a breakdown of what each approach entails.

Installation Approach Comparison Professional vs DIY

| Factor | Professional Installation | DIY Installation |

|---|---|---|

| Expertise & Compliance | Certified technicians ensure installation meets all local codes (e.g., LAHD) and manufacturer specs. | High risk of non-compliance, safety issues, and incorrect setup. |

| Warranty Protection | Preserves your manufacturer's warranty. Many warranties are voided by improper installation. | Voids the warranty in almost all cases if a failure is traced back to installation error. |

| Time & Labor | Frees up you and your staff to focus on running the business. The job is done quickly and efficiently. | Requires significant time and physical labor from your team, causing operational disruptions. |

| Liability | The installation company is insured and liable for any damage that occurs during the process. | You assume all liability for property damage, personal injury, and equipment failure. |

| Cost | Higher upfront cost for labor. | Lower upfront cost, but high potential for expensive long-term repairs and replacement. |

| Tools & Equipment | Professionals arrive with all necessary specialized tools and equipment. | May require you to rent or purchase specialized tools you'll rarely use again. |

Ultimately, while the upfront cost of a professional installer might seem like an extra expense, it's often a small price to pay for the assurance that your new, expensive equipment is set up for a long and productive life.

Weighing the Risks of a DIY Approach

So, is there ever a good time to do it yourself? Maybe for a small, simple plug-in unit in a low-traffic area where a failure wouldn't be catastrophic. But when you're talking about the heavy-duty equipment needed in most restaurants—especially the large systems you see in Korean BBQ joints or busy Chinese kitchens—the risks are just too high.

When you go the DIY route, you take on 100% of the liability. If the unit damages your floor, shorts your electrical system, or fails a health inspection, that's all on you. You also lose out on a technician’s experienced eye for spotting problems you'd never think of, like poor airflow in a corner that will cause your unit to overheat and die during the first real LA heatwave. This is especially true for complex setups; when you're looking at something like a walk-in cooler and freezer combination, the value of having an expert on-site is immeasurable.

At the end of the day, paying for a professional commercial refrigerator installation is an investment in your restaurant's future. It guarantees you're compliant, protects your warranty, and prevents the kind of expensive breakdowns that can bring a kitchen to a grinding halt.

Managing Delivery and Final Unit Placement

The day your new refrigerator arrives is a big deal for any LA restaurant or food truck. The first few hours are crucial—how you handle the unit now can pretty much define its entire working life. From the second that delivery truck pulls up, your full attention is needed to get it from the pallet to its new home in your kitchen without a hitch.

Before you even think about putting a pen to that delivery receipt, give the packaging a serious once-over. You're looking for any signs it had a rough trip—dents, punctures, or corners that look like they've been in a fight. If you spot anything that looks off, whip out your phone, snap some pictures, and make a detailed note on the bill of lading. Do this before the driver leaves. The second you sign, you're accepting the unit as is, and good luck trying to file a freight claim after the fact.

From Curb to Kitchen

Once you've given the packaging the all-clear, the real workout begins. Moving these units is no joke. Whether you're trying to squeeze it into a Thai food truck or wheeling it across a spacious Mexican restaurant kitchen, safety comes first. Grab a heavy-duty dolly, and make sure you have enough people on hand to carefully guide it through doorways and around tight corners.

After you've uncrated it, it's time for another, closer look. Check every surface for damage that might have been hidden by the box. Make sure all the shelves and parts are there, and give the door gaskets a good inspection for any nicks or tears.

I can't stress this next part enough: leveling the unit is one of the most overlooked yet critical steps. If your refrigerator is wobbly, the doors won't hang right, and the gaskets won't create an airtight seal. That means cold air is constantly leaking out, forcing your compressor to run 24/7.

Use a level and adjust the feet until it's perfectly solid and even on all sides. A level unit not only seals correctly but also makes sure condensation drains the way it's supposed to, so you don't end up with water pooling on the floor.

Final Connections and Safety Checks

With the refrigerator perfectly leveled and in place, you can tackle the final hookups. This means plugging it into its own dedicated electrical outlet and connecting any water or drain lines. Take your time here and double-check that every connection is tight and completely leak-free.

Getting the delivery and placement right is about more than just moving a heavy box; it's a direct investment in your equipment's long-term health and efficiency. As the commercial refrigeration market grows, energy performance is a huge deal for businesses, especially in LA's competitive food scene. A professional installation that follows NSF standards can actually boost a unit's efficiency by 15-25%. That's a big deal when you consider that many commercial kitchens in the U.S. waste 10-15% of their energy just from shoddy equipment setups. You can discover more insights about the commercial refrigeration market and its growth.

Powering Up and Testing for Peak Performance

Your new commercial refrigerator is in place, level, and ready to become the workhorse of your kitchen. But before you plug it in and start loading it up, hold on. This first startup, what we call commissioning, is your single best chance to spot a small problem before it turns into a catastrophic failure—and a few thousand dollars of spoiled inventory for your Los Angeles restaurant.

First things first: be patient. After all that jostling during delivery, the unit needs to sit unplugged for at least four to six hours. A full day is even better. This gives the compressor oil, which gets sloshed around during transit, time to settle back where it belongs. Firing it up too soon forces the compressor to run dry, a mistake that can kill a brand-new machine almost instantly.

The First Cool-Down and Calibration

Once you’ve given it time to rest, it's go-time. Plug it in and watch the initial cool-down cycle like a hawk. Don’t just rely on the built-in thermostat; grab a separate, trustworthy thermometer and place it inside to see what’s really happening. You need that unit to hit and hold a food-safe temperature, which is consistently below 40°F.

While it's getting down to temp, run through these quick but crucial checks:

- Door Seal Verification: The old dollar-bill trick still works. Close the door on a bill and try to pull it out. If it comes out with no resistance, you’ve got a bad seal, which means you're leaking cold air and wasting money.

- Defrost Cycle Check: Crack open the manual and get familiar with the automatic defrost cycle. You need to confirm it’s kicking on when it’s supposed to. A faulty defrost system will lead to ice buildup on the evaporator coils, absolutely wrecking its cooling power.

A proper startup is non-negotiable for any LA kitchen, from a Korean BBQ spot to a high-volume Chinese restaurant. This initial diligence ensures your unit runs efficiently from day one, preventing costly breakdowns during a dinner rush.

Minimizing downtime is everything for a Los Angeles restaurateur. A solid commercial refrigerator installation that follows California's Title 24 energy standards can slash your energy use by up to 30%, which goes straight to your bottom line. For bigger walk-ins or reach-ins, you also have to be certain your electrical setup can handle a three-phase power installation, as it's often essential for performance.

One last thing—don't forget to register your warranty. It’s a simple step that protects your investment and makes sure you have access to authorized help if you ever need it. For more ways to get the most out of your machine, check out our guide on energy-efficient commercial refrigerators.

Common Installation Questions from LA Restaurant Owners

When it comes to getting a new commercial refrigerator set up, we hear a lot of the same questions from chefs and restaurant owners all over Los Angeles. Getting the right answers can be the difference between a smooth launch and a costly headache. Here are some of the most common things we get asked, with practical advice for your LA kitchen.

What Are the Most Common Installation Mistakes to Avoid

Honestly, the biggest slip-ups almost always happen long before the delivery truck even shows up. Many restaurant owners, especially when they're in a rush, forget to measure every single doorway, tight corner, and hallway on the delivery path. This can turn installation day into a logistical nightmare, leaving your brand-new unit stuck outside.

Another mistake we see all the time is placing the refrigerator right next to a heat source, like a deep fryer or a wok range in a Chinese kitchen, or cramming it into a spot with zero airflow. That forces the compressor to work way too hard, which sends your energy bills through the roof and shortens the life of your equipment. Just as bad is skipping the leveling step. A wobbly fridge means the doors won't seal tight, wasting energy and putting your food safety at serious risk.

The good news? These expensive problems are almost entirely preventable. A simple, thorough pre-installation checklist—covering measurements, placement, and utility checks—is your best defense against these common pitfalls.

Putting together a quick checklist can save you from some major headaches and unexpected costs down the road.

How Long Should I Wait to Plug In My New Refrigerator

Patience is everything at this stage. Once your new commercial refrigerator is in its final spot, you absolutely must let it stand completely unplugged for at least four to six hours. If you can swing it, waiting a full 24 hours is even better.

There's a really important reason for this. During shipping, the lubricating oil inside the compressor can get sloshed around into the refrigerant lines. If you turn the unit on too soon, you're essentially forcing the compressor to run dry, which can cause it to fail catastrophically right away.

Letting the refrigerator sit undisturbed allows gravity to do its thing. The oil will slowly drain back into the compressor where it belongs. This simple act of waiting is one of the easiest ways to protect your investment and ensure your new equipment has a long, reliable life.

Does My Commercial Refrigerator Need Special Ventilation

Yes, and this is completely non-negotiable for any commercial kitchen, especially in the tight spaces you often find in Los Angeles. Commercial refrigerators generate a lot of heat as part of their cooling cycle, and they need room to breathe to get rid of it.

Your manufacturer's manual will have a section that lays out the specific clearance requirements. This usually means leaving at least a few inches of open space on the sides, back, and top of the unit. Ignoring these guidelines is just asking for trouble.

When heat gets trapped around the refrigerator, the compressor is forced to run constantly just to keep things cool. This not only makes your electricity bill skyrocket but also puts a ton of strain on the whole system. Over time, that leads to breakdowns, and they always seem to happen during the dinner rush. In any LA Korean BBQ joint, Mexican restaurant, or food truck, planning for proper ventilation from the start is one of the smartest operational decisions you can make.

For all your kitchen needs, from high-performance refrigerators to essential cooking equipment, Los Angeles Restaurant Equipment has you covered. We offer a wide selection of professional-grade gear with free delivery and flexible financing to help your business thrive. Explore our full catalog at https://losangelesrestaurantequipment.com.