Choosing a Condensing Unit for Walk In Cooler in Los Angeles

Share

The condensing unit for a walk in cooler is basically the heart of your entire refrigeration system. It's the heavy-lifting component that pulls heat out from inside your cooler and dumps it outside, making sure all your valuable ingredients stay perfectly chilled, safe, and ready to go for your customers.

The Engine Behind Your Restaurant's Freshness

Think of the condensing unit as the workhorse of your Los Angeles kitchen. It’s humming away in the background, keeping the lettuce crisp for a Hollywood Thai food spot or preserving the quality of prime cuts for a Korean BBQ joint in K-Town. Without a powerful condensing unit, your walk-in cooler is really just an expensive, insulated closet—a major problem for any restaurant equipment setup.

Understanding how this vital piece of your commercial refrigerator works is the first step in protecting your inventory and your bottom line. The process is a lot like the A/C in your car. It circulates refrigerant to soak up the heat inside the walk-in, then carries that heat outside and releases it. This constant cycle is what keeps the temperature low and your food safe.

Why This Matters for LA Food Businesses

For any food business in Los Angeles, from a busy Mexican food truck in East LA to a fine-dining Japanese restaurant in Santa Monica, a reliable condensing unit isn’t just nice to have—it's absolutely essential. If that unit fails, you’re looking at catastrophic inventory loss, which can easily cost you thousands of dollars and hurt your reputation.

A few key parts make this whole system work:

- The Compressor: This is the muscle. It pressurizes the refrigerant gas, kicking off the whole heat-transfer cycle.

- The Condenser Coils: This is where the hot, high-pressure refrigerant gets to cool down by releasing its heat into the air.

- The Fan: A fan blows air over the condenser coils to speed up the cooling process and get rid of the heat faster.

Getting a handle on how your condensing unit works isn’t just about buying equipment. It’s an investment in the consistency, safety, and profitability of your entire culinary operation, whether you serve Chinese, Thai, or Mexican cuisine.

This whole process is a nonstop battle against the heat from your kitchen and the relentless Southern California sun. A good, properly functioning unit ensures you're always winning that fight, keeping your ingredients well within the strict temperature ranges required by the health department.

Ultimately, your entire commercial refrigeration setup, including commercial refrigerators and freezers, lives or dies by the performance of this one component. Choosing the right one, getting it installed correctly, and keeping up with maintenance are non-negotiable for any successful Los Angeles restaurant. This basic understanding is the foundation for making smart decisions that protect both your food and your profits.

Properly Sizing Your Unit for the LA Climate

Picking the right size condensing unit is one of the most important calls you'll make for your Los Angeles restaurant—and it’s where a lot of expensive mistakes are made. If you go too small, the unit will constantly be fighting a losing battle to keep your inventory cool, putting you at risk for food spoilage and health code dings. On the flip side, a unit that’s too big will constantly turn on and off, wasting a shocking amount of electricity and sending your utility bills through the roof.

Finding that sweet spot isn't just about matching numbers on a spec sheet. It's about really understanding how your kitchen works day-in and day-out, especially in the tough Southern California heat. A unit that’s perfect for a small food truck in Silver Lake would get absolutely crushed trying to keep up with a high-volume Japanese restaurant in Downtown LA.

Key Factors for Sizing in Los Angeles

To get the size right, you have to look beyond the simple dimensions of your walk-in box. Several things are always changing, and each one adds to the "heat load" your condensing unit needs to beat.

- Cooler Volume: This is your starting line. You need to calculate the total cubic footage of your walk-in (Length x Width x Height) to get a baseline for the capacity you'll need.

- Ambient Temperature: Los Angeles summers are no joke. Your unit has to be strong enough to pump out heat even when it's over 90°F outside, which is a regular day in the San Fernando Valley.

- Product Load: What you’re chilling matters. A cooler packed tight with dense items like cases of beer or huge cuts of meat for a Korean BBQ joint holds way more heat than one filled with lighter produce for a Thai kitchen.

- Door Openings: In a busy kitchen, that cooler door is swinging open all the time, letting in waves of warm, humid air. Every opening adds to the heat load your unit has to deal with.

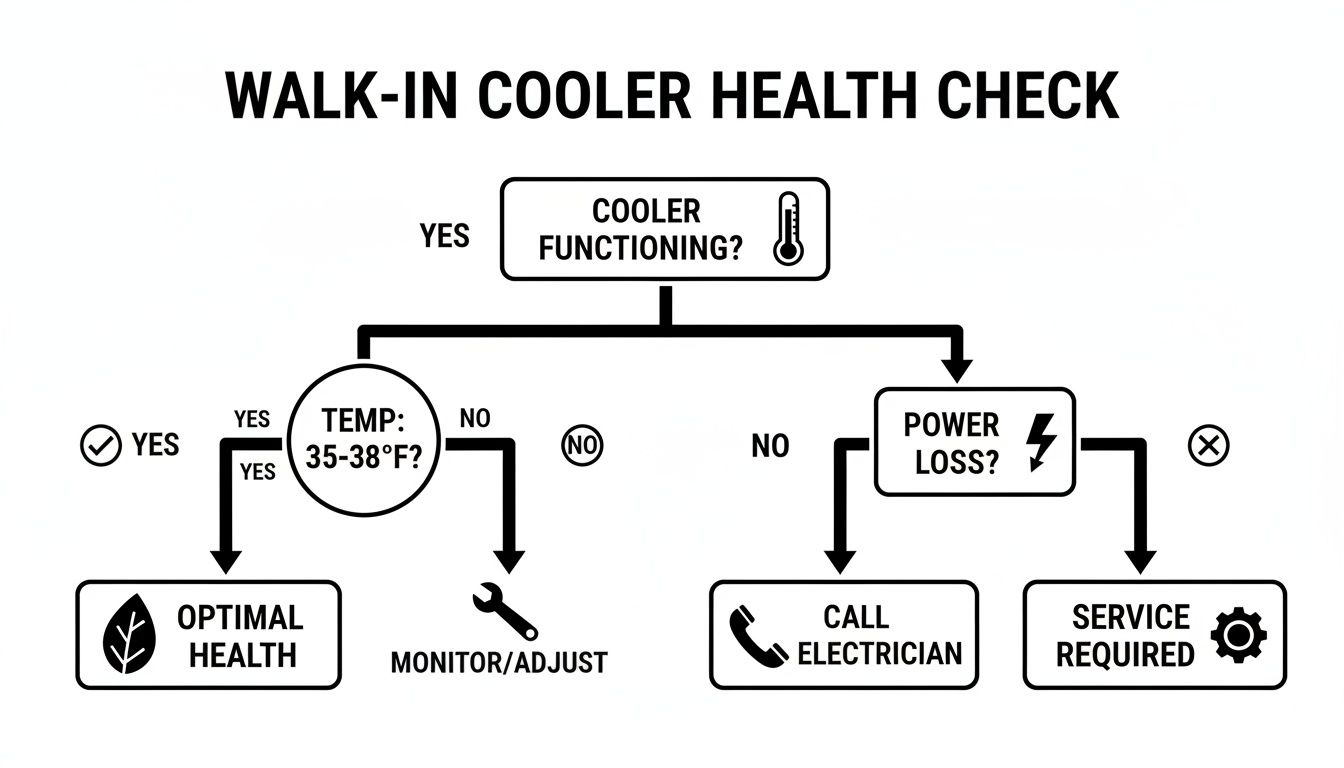

If you’re not sure where to start, this quick health check can help you figure out if your current walk-in is struggling before you even think about a replacement.

This flowchart walks you through the basics, reminding you to check the simple stuff like temperature and power if things aren't working right. You don't want to buy a new unit if it's just a tripped breaker!

For Los Angeles restaurant owners, a few variables are absolutely non-negotiable when sizing a condensing unit. This table breaks down what you need to focus on.

Key Sizing Factors for Your Condensing Unit

| Sizing Factor | What It Means for Your Cooler | Why It's Critical in Los Angeles |

|---|---|---|

| Ambient Temperature | The maximum outdoor temperature your unit can handle while still cooling effectively. | LA heatwaves, especially in the valleys, can push units to their limit. You need one rated for our high summer temps. |

| Product Load & Type | How much product you store and how dense it is. Meats and liquids hold more heat than vegetables. | A K-Town Korean BBQ spot has a much higher heat load from its beef and pork than a Venice juice bar does from its produce. |

| Door Openings Per Hour | How frequently your staff accesses the cooler, especially during peak service hours. | A busy DTLA kitchen serving Chinese food during lunch rush introduces a massive amount of warm air, requiring a more robust unit to recover quickly. |

| Insulation (U-value) | The quality and thickness of your walk-in's wall panels. Better insulation means less heat gets in. | Older buildings in Hollywood or Echo Park might have less effective insulation, meaning your unit has to work harder. |

Getting these details right is the difference between a system that runs smoothly for years and one that gives you constant headaches.

Real-World LA Scenarios

Let’s put this into practice. A busy Mexican restaurant in East LA is going to need a much beefier condensing unit. They’re storing dense products like meats and cheeses, and the kitchen staff is in and out of that cooler constantly during service.

Now, think about a small cafe in Pasadena. They might have less foot traffic and store lighter items like pastries and milk. Their unit won't need to work nearly as hard. Sizing is all about matching the equipment's power to the real-world demands of your business, not just the size of the box. You can learn more about picking the right setup in our guide to commercial walk-in refrigerators.

A properly sized condensing unit isn't an expense—it's insurance for your inventory and a crucial tool for managing your operational costs. Investing the time to calculate your needs accurately will pay dividends for years.

The global condensing unit market, which is the heart of every walk-in cooler, shot up to USD 43.4 billion in 2024 and is on track to hit USD 79.9 billion by 2033. This growth is all about the refrigeration systems that keep restaurants and commercial kitchens running worldwide. Here in the U.S., North America owned 48.7% of the walk-in market back in 2020, which shows just how much LA operators depend on these units.

Remote vs Self-Contained Units for Your Kitchen

When you're picking a condensing unit for a walk in cooler, you’ll hit a major fork in the road: do you go with a remote or a self-contained system? This choice will have a real impact on your kitchen’s vibe and your budget. Each setup has its own perks, perfect for different kinds of Los Angeles foodservice spots, from a sprawling restaurant to a cozy food truck.

It all comes down to where you want the heat and noise to end up. A remote unit sticks the condensing unit outside or in a separate room, while a self-contained system builds it right into the walk-in, usually on top. Getting a handle on the trade-offs is the first step to creating a workspace that’s both efficient and comfortable.

The Case for Remote Condensing Units

For a lot of busy Los Angeles restaurants, remote systems are the way to go, and it’s easy to see why. By moving the condensing unit outdoors—maybe up on the roof or in a space out back—you get rid of two of the biggest kitchen headaches: heat and noise.

This setup makes for a much cooler and quieter kitchen. If you’ve got an open-kitchen concept in West Hollywood serving Japanese cuisine or a small, customer-facing cafe in Silver Lake, cutting down on the racket and extra heat from your refrigeration can make a world of difference for your staff and your guests.

On top of that, remote units are real winners when it comes to energy efficiency. Kitchens are already hot places, and a condensing unit struggling in that heat has to work a lot harder. Putting it outside where it can breathe and cool down easily takes the strain off the compressor, which often means lower electricity bills.

You can see how popular this approach is just by looking at the numbers. In the commercial refrigeration world, remote condensing units are the clear favorite for walk-in coolers, holding a massive 48% market share in 2025. Their smart design, which cuts noise and dumps heat outside, makes them a perfect match for bustling LA kitchens. You can find more details on the walk-in cooler market over at Future Market Insights.

The Simplicity of Self-Contained Units

While remote systems have some serious advantages, self-contained units offer a simple, all-in-one package that’s usually quicker and cheaper to get up and running. You might hear them called top-mount or package units, and they come with all the refrigeration parts tucked into one box that just sits right on top of the walk-in cooler.

This design has some handy perks, especially for businesses with straightforward needs or a tighter budget.

- Lower Upfront Cost: Self-contained units typically cost less to buy and are simpler to install, since you don't need to run long refrigerant lines.

- Space Efficiency: The whole system is right on the cooler, so you don't need to find extra room on the ground or roof. That’s a huge bonus for Los Angeles food trucks or kitchens in packed areas like Downtown LA.

- Simplified Maintenance: When all the parts are in one easy-to-reach spot, service calls and repairs can often be done faster and with less hassle.

A self-contained condensing unit for a walk-in cooler is a plug-and-play solution ideal for new restaurant startups, mobile kitchens like food trucks, or any operation where installation speed and budget are top priorities.

Of course, there are trade-offs. The unit will pump its exhaust heat right into your kitchen, which could make your air conditioning work harder and create a warmer environment for your team. They also make more noise, which might be an issue depending on how close your kitchen is to your dining area.

Making the Right Choice for Your LA Business

So, remote or self-contained? The right answer really depends on your specific situation. A high-volume Thai spot in Koreatown with a hot, busy kitchen line would get a huge benefit from a remote system that keeps the staff cool and the energy bills down.

On the other hand, a small food truck slinging Mexican food for the lunch crowd in Santa Monica would probably find a self-contained unit to be a perfect fit. Its compact, all-in-one design saves precious space and makes setup a breeze, getting them in business that much faster. Just think about your kitchen’s size, how much heat it generates, what your noise tolerance is, and what your budget looks like to figure out which system will best serve you.

Installation Best Practices for LA Businesses

Let's be blunt: even the most expensive, top-of-the-line condensing unit for a walk in cooler is worthless if it's installed badly. For any restaurant owner in Los Angeles, getting the installation right the first time is the single best way to protect your investment, keep your food safe, and save yourself from major headaches down the road. This isn't just about hooking up a few pipes and wires; it's about setting up your restaurant equipment to handle the specific challenges of the LA climate.

Think of a proper installation as giving your equipment a fighting chance for a long, efficient life. Simple decisions made on day one—like where you put the unit and how the refrigerant lines are run—will directly hit your utility bills and determine how long the system lasts. Nailing the basics from the get-go is the key to getting peak performance the moment you flip the switch.

Location and Airflow Are Everything

In Southern California, the single most critical factor for your condensing unit is airflow. It has one job: get rid of heat. If it can't breathe, it can't cool. Shoving it into a tight, enclosed space or cramming it against a wall is a guaranteed way to burn out the compressor.

- Rooftop Placement: This is the go-to choice for many LA businesses. It gets the unit out of the way, usually guarantees fantastic, unobstructed airflow, and cuts down on noise at ground level.

- Ground-Level Placement: This makes maintenance a bit easier, but you have to be smart about it. Make sure there’s plenty of clearance on all sides—a good rule of thumb is at least 2-3 feet—and keep it far away from heat sources like a kitchen exhaust vent or the blistering afternoon sun.

Your condensing unit’s location directly impacts its efficiency. A unit starved for air is like a marathon runner trying to breathe through a coffee stirrer—it’s going to work way too hard and fail way too soon.

No matter where you put it, the goal is always the same: give that unit plenty of fresh air so it can easily dump the heat it pulled from your walk-in. For any business, understanding the basics of Commercial AC Unit Installation is a huge help, as a lot of the same principles apply here.

Hire a Pro and Handle LA Codes Correctly

This is not a DIY job. A refrigeration system, whether it's for commercial refrigerators or freezers, is a closed, high-pressure loop that requires specialized tools and deep know-how. You absolutely have to hire a certified HVAC-R (Heating, Ventilation, Air Conditioning, and Refrigeration) technician. They know how to handle refrigerant safely, make sure the lines are properly sized and sealed, and wire everything up to code.

On top of that, Los Angeles has its own set of building codes and permit requirements for this kind of equipment. A professional will already know the local rules, ensuring your installation is fully compliant and saving you from potential fines or shutdown orders. Our own guide on commercial refrigerator installation dives deeper into what this process looks like.

Finally, a pro will do the final checks to make sure the system has the exact right amount of refrigerant and is running at the manufacturer's specified pressures. This last step is crucial for both cooling power and energy efficiency. Paying for a professional installation truly pays for itself by preventing expensive repairs and making sure your unit runs like a champ for years.

A Practical Maintenance and Troubleshooting Guide

In your Los Angeles kitchen, the condensing unit for your walk-in cooler is easily the hardest-working piece of equipment you own. It runs around the clock, protecting thousands of dollars in food inventory for your Korean, Chinese, or Mexican dishes. Just like the engine in your car, it needs regular check-ups to keep it running right. Putting off maintenance is just asking for a total system failure during a brutal August heatwave—leading to spoiled product, unhappy customers, and a huge emergency repair bill.

This guide lays out a simple maintenance plan and some quick troubleshooting tips for you and your staff. Catching small problems before they turn into catastrophes will save you from expensive downtime and keep your whole refrigeration system humming along. Trust me, being proactive is always cheaper than being reactive.

Building a Simple Maintenance Routine

Consistency is everything. You don't need to be an HVAC pro to handle the basic upkeep that can add years to your unit's life. A simple, repeatable schedule makes sure these critical jobs don't fall through the cracks when things get hectic.

Here's a practical schedule you can start using in your restaurant today:

- Monthly Coil Cleaning: Think of the condenser coils as your unit’s lungs—they have to be able to breathe. Here in LA, dust, grease from kitchen vents, and smog can cake onto these fins in no time, trapping heat and forcing your compressor to work way too hard. Once a month, kill the power to the unit and gently clean the coils with a soft brush and a proper coil cleaning solution.

- Quarterly Fan Inspection: Take a look at the condenser fan blades for any obvious damage or debris. Listen for weird noises like rattling or grinding, which can be a sign of a failing motor bearing. A bad fan is one of the top causes of overheating.

- Semi-Annual Professional Tune-Up: Get a certified technician out to do a full inspection twice a year. They'll check refrigerant levels (a system should never "use up" refrigerant; if it's low, you have a leak), test all the electrical connections, and lubricate the motors. This is a non-negotiable investment if you want your equipment to last.

Think of routine maintenance as your first line of defense. A 15-minute coil cleaning each month can prevent a $1,500 emergency compressor replacement down the line. It's the best return on investment you can make for your kitchen's infrastructure.

Troubleshooting Common Cooler Problems

Even with perfect maintenance, things can go wrong. When your walk-in starts acting up, it can send a wave of panic through the kitchen. But before you make that emergency service call, there are a few things your team can check to figure out what's going on—and maybe even fix it on the spot.

This table runs through the most common issues LA restaurant owners run into, what's likely causing them, and the first steps you can take. Always remember to cut the power at the breaker before you or your staff start physically checking the unit. Running through these simple checks can often save you the cost of a service call for something minor, like a tripped breaker or a blocked vent.

Common Walk-In Cooler Problems and First Steps

| Symptom | Potential Cause | What You Can Do Now |

|---|---|---|

| Cooler Isn't Cold Enough | Dirty condenser coils, low refrigerant, or an iced-up evaporator coil inside the walk-in. | Check and clean the outdoor condenser coils first. Make sure nothing is blocking airflow to the evaporator inside. If it's still warm, you likely have a refrigerant leak that needs a pro. |

| Unit Runs Constantly | A bad door seal, the door is being opened too often, or the unit might be undersized for the LA heat. | Inspect the door gasket for any tears or gaps and replace it if it's worn out. Remind staff to keep the door closed. If it still runs nonstop on a hot day, you may need a system evaluation. |

| Unit is Leaking Water | Clogged drain line. | The evaporator coil pulls moisture from the air, and that condensation has to drain away. Find the drain line and check if it's clogged. A simple cleaning usually solves this common problem. |

| Unit is Unusually Noisy | Worn fan motor bearings or parts have come loose. | Listen closely and try to pinpoint where the noise is coming from. If you hear a grinding or squealing sound, shut the unit down and call a technician to prevent more serious damage to the fan motor. |

Tackling these basic checks first empowers your team and can get your kitchen back on track faster. If the problem is something bigger, you'll be able to give your technician a much clearer idea of what's happening when they arrive.

Maximizing Energy Efficiency and Long-Term Savings

In a city like Los Angeles, where every single operational cost counts, your condensing unit for a walk in cooler isn't just another line item on an invoice. Think of it as a strategic investment in your restaurant's future profitability. A modern, energy-efficient unit can seriously slash your monthly utility bills, which goes right back into your pocket.

This isn't about saving a few pennies here and there. It's about turning a major cost center into a source of real operational efficiency. The right equipment makes your whole kitchen more sustainable and financially sound, whether you're running a busy Chinese restaurant in the San Gabriel Valley or a Thai food truck in Venice.

Key Features That Drive Down Costs

Today's condensing units are packed with smart technology built to lower energy use without sacrificing an ounce of cooling performance. These aren't just minor tweaks; they're major upgrades that pay for themselves over time.

When you're shopping for a new unit, keep an eye out for these game-changing features:

- High-Efficiency Fan Motors (EC Motors): These aren't your grandpa's fan motors. Electronically Commutated (EC) motors can be up to 70% more efficient than the old-school models. They also run cooler and last longer, using way less electricity to move air over the condenser coils.

- Intelligent Control Systems: Advanced controls are like a brain for your cooler, monitoring temperature and pressure with incredible precision. They can adjust the compressor and fan speeds to match the exact cooling demand, which stops the wasteful on/off cycling that sends energy bills through the roof.

- Variable Frequency Drives (VFDs): Think of these as a smart gas pedal for your compressor motor. Instead of running at full throttle all the time, a VFD lets the motor ramp up or down as needed. This leads to huge energy savings, especially during slower, off-peak hours. To really get the most out of this tech, you'll want to maximize VFD energy savings in your setup.

Connecting Efficiency to Your Bottom Line

Every one of these techy features translates directly into dollars and cents. A high-efficiency motor means a lower electricity bill every month. An intelligent control system cuts down on wear and tear, extending your compressor's life and helping you avoid those dreaded emergency repair bills.

An upfront investment in an energy-efficient condensing unit is one of the smartest financial decisions a Los Angeles restaurant owner can make. The operational savings don't just offset the initial cost—they generate a positive return for years to come.

For instance, a unit with an EC motor might have a higher sticker price, but the drop in your monthly Southern California Edison bill can lead to a payback period of just a couple of years. After that, all those savings go straight to your profit margin. You can discover even more ways to trim your kitchen's energy use by checking out our guide on energy-efficient commercial refrigerators. By prioritizing these features, you're not just buying equipment; you're building a more profitable and resilient restaurant.

Your Top Questions Answered

When it comes to the heart of their refrigeration system, Los Angeles restaurant owners have a few key questions. We’ve pulled together the most common things people ask about the condensing unit for a walk in cooler to give you clear, straight-up answers for your Mexican, Japanese, Korean, or Thai kitchen.

What’s the Perfect Temperature for a Walk-In Cooler?

For most of what you're storing, you’ll want to keep your walk-in humming along between 35°F and 38°F. This is the sweet spot for keeping everything from crisp produce to dairy and prepped ingredients safely chilled, all while staying on the right side of LA County health codes and avoiding freezer burn.

Of course, what you're storing makes a difference. For example:

- Fresh Meats: You’ll get a longer shelf life by keeping them closer to 32°F.

- Produce: A lot of greens and veggies do better around 38°F to keep from wilting.

- Beer Kegs: The ideal serving temp is typically between 36°F and 38°F.

It's always a good idea to double-check the best storage temps for your most expensive inventory, whether it's fish for a Japanese restaurant or meats for a Mexican one.

How Often Does My Condensing Unit Need Service?

In a busy LA restaurant, we can't stress this enough: get it professionally serviced at least twice a year. A tune-up in the spring gets it ready for the brutal summer heat, and another check-up in the fall makes sure it runs smoothly through the cooler months. Think of it as the best way to catch a small problem before it turns into a total nightmare during a Saturday night dinner rush.

Don't think of twice-yearly professional maintenance as a cost. It's an insurance policy against thousands of dollars in spoiled food and emergency repair bills. For any serious restaurant operator, it's non-negotiable.

Can I Just Install a Condensing Unit Myself?

Definitely not. This is a job that involves high-pressure refrigerant lines, tricky electrical work, and knowing the ins and outs of Los Angeles building codes. It’s strictly for certified and licensed HVAC-R technicians. Trying to DIY this kind of installation will void your warranty, create major safety hazards, and pretty much guarantee the unit will run poorly and fail way sooner than it should.

What Are the Warning Signs That My Condensing Unit Is Failing?

Keep an eye out for a few tell-tale signs that your unit needs help, and fast. If you notice the cooler isn't holding its temperature, your power bills are suddenly through the roof, or you hear strange grinding or squealing sounds, it’s time to call a pro. Another big red flag is a unit that runs constantly without ever shutting off—that means it's fighting a losing battle against the heat load.

Ready to make sure your kitchen's refrigeration is powerful, reliable, and efficient? The experts at Los Angeles Restaurant Equipment are here to walk you through selecting the perfect condensing unit for your operation, whether you're running a food truck or a high-volume restaurant. Check out our lineup of Atosa commercial refrigeration and keep your cool with equipment you can really count on.