Equipment for Butcher Shop: Essential Gear Guide

Share

Opening a butcher shop, especially in a food-obsessed city like Los Angeles, is about more than just skill—it's about having the right tools for the craft. The equipment you choose is the backbone of your business, directly shaping your efficiency, the quality of your cuts, and ultimately, your bottom line.

This guide is your complete roadmap to outfitting a modern butchery from scratch, covering every piece of gear you'll need, from processing machines to the customer-facing displays that make your products shine.

Building Your Butchery From The Ground Up

Don't think of your equipment as just a shopping list. Instead, picture it as a complete ecosystem built for a specific workflow. Every single piece, from the beast of a band saw in the back room to the gleaming refrigerated display case out front, has a vital part to play.

When you've got the right setup, you can handle busy days, blow past Los Angeles County's tough safety standards, and create the kind of artisanal products that keep people coming back. In a city where food is everything—from high-end steakhouses to food trucks grilling up Korean BBQ and carne asada—the quality of your cut is what sets you apart. Your equipment is what makes that quality possible, day in and day out.

The Core Equipment Categories

Let's break down the essential equipment categories that form the foundation of any successful butcher shop. Understanding these is the first step to building a workspace that’s both functional and profitable.

- Meat Cutting and Processing: This is the heavy-duty machinery that does the real work. We're talking about band saws, meat slicers, and grinders that turn huge primal cuts into beautiful, retail-ready products.

- Cold Storage and Refrigeration: This is, without a doubt, the most critical part of your setup. It's what protects your inventory and includes everything from massive walk-in units to the merchandiser display cases your customers see.

- Value-Added Product Tools: This is where you make your money. Gear like sausage stuffers and vacuum sealers lets you turn trim into high-margin items like house-made sausages or marinated meats perfect for Mexican, Japanese, or Thai cuisine.

- Sanitation and Support Supplies: These are the unsung heroes. Sinks, prep tables, scales, and, of course, a great set of knives are all essential for keeping your shop clean, safe, and compliant.

A well-equipped butchery runs like a finely tuned assembly line. The workflow should flow logically from receiving and storage to processing and the final sale, which minimizes any chance of cross-contamination and makes the whole operation run smoother.

Proper cold storage is probably the single most important investment you’ll make. It’s what stands between your entire inventory and spoilage, making it the true cornerstone of your business. To really get a handle on how these systems work, you can check out our in-depth guide on walk-in cooler and freezer combination units, which are absolutely fundamental for any serious butcher.

Now that we have the big picture, we can start diving into each equipment category to give you the knowledge you need to build your business from the ground up.

At a Glance: Your Butcher Shop Equipment Checklist

Before we get into the nitty-gritty of each piece of equipment, here's a quick cheat sheet. Think of this table as your starting point—a high-level overview of the essential tools you'll need to get your shop running.

| Category | Primary Function | Key Examples |

|---|---|---|

| Processing | Breaking down primal cuts into retail portions. | Meat Grinders, Band Saws, Meat Slicers |

| Cold Storage | Protecting inventory and ensuring food safety. | Walk-In Coolers/Freezers, Refrigerated Display Cases |

| Value-Add | Creating high-margin specialty products. | Sausage Stuffers, Vacuum Sealers, Meat Tenderizers |

| Sanitation | Maintaining a clean, compliant workspace. | 3-Compartment Sinks, Stainless Steel Prep Tables |

| Support | Facilitating daily operations and sales. | Meat Scales, Knives, Wrapping Stations, POS System |

This checklist covers the foundational pillars of a modern butchery. As we move through this guide, we'll explore each of these categories in much greater detail, helping you choose the right size and model for your specific needs.

The Workhorses: Core Meat Cutting Equipment

Behind the gleaming display cases and friendly counter service of every great Los Angeles butcher shop is the engine room. This is where the real work happens—where primal cuts are broken down into the beautiful steaks, roasts, and ground meat your customers are looking for. Your core cutting equipment is absolutely non-negotiable; these are the workhorses that determine your shop's capacity and quality.

Choosing the right machines is a lot like hiring the most critical members of your team. You need them to be powerful, precise, and durable enough to handle the daily grind. Think of your band saw as the heavy hitter, breaking down big, bone-in primals with force and accuracy. Your slicer, on the other hand, is for the fine-detail work, creating those perfectly consistent portions with a delicate touch.

Ultimately, the safety and success of your entire operation hinge on this equipment. Investing in solid, well-built machinery doesn't just make you more efficient; it protects your staff and ensures every cut you sell meets the highest standard.

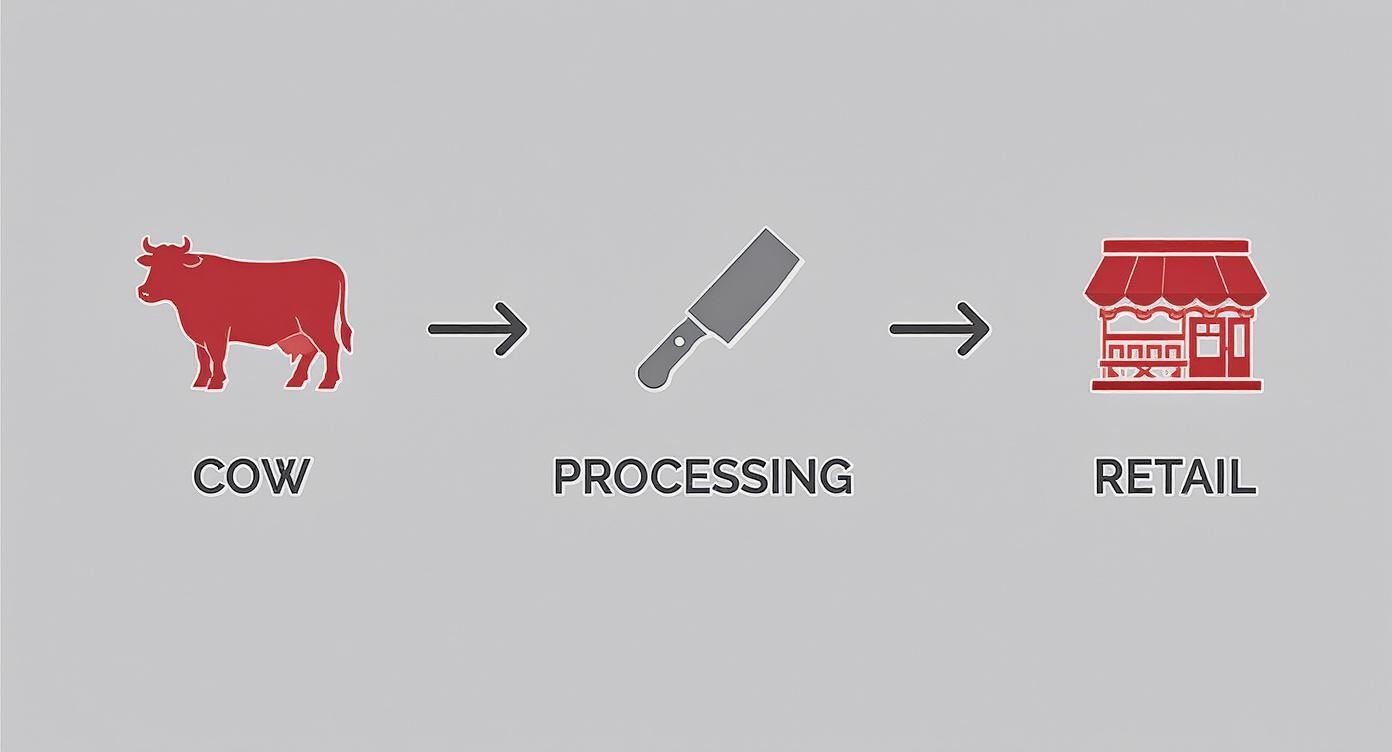

This simple visual shows how meat moves through your shop—from the delivery door, through processing with your core equipment, and finally to the retail counter.

You can see how central the processing stage is. It’s the critical link between the bulk primals you buy and the finished products your customers take home.

The Indispensable Meat Band Saw

For any butcher, the commercial meat band saw is easily the most important piece of processing equipment you'll own. It’s what lets you break down massive, bone-in cuts like a side of beef or a whole lamb with speed and precision. Trying to do that by hand would be an absolute nightmare of time and labor.

When you're shopping for a band saw, you need to look for features that guarantee both performance and safety:

- Stainless Steel Construction: This is a must-have for hygiene and a long lifespan. A stainless steel frame won't corrode and is much easier to sanitize, which is a huge deal when it comes to passing LA County health inspections.

- Horsepower (HP): For a standard retail butcher shop, a motor between 1.5 to 3 HP is the sweet spot. That’s enough power to slice through dense bone without the machine bogging down.

- Safety Features: Any modern saw worth its salt will have blade guards, an emergency shut-off, and tool-free disassembly for safe, deep cleaning. Proper training on these features is key to keeping everyone safe.

A reliable band saw is what allows you to buy those larger, more cost-effective primals, giving you way more control over your inventory and profit margins.

Precision and Consistency with a Commercial Meat Slicer

While the band saw does all the heavy lifting, the commercial meat slicer brings the finesse. It's essential for a huge range of products that demand consistency. From paper-thin prosciutto for charcuterie boards to perfectly uniform slices of beef for Korean BBQ or Japanese shabu-shabu, a quality slicer delivers a result you could never achieve by hand. That consistency is key for portion control, predictable pricing, and making your products look professional.

You’ve got two main types to think about:

- Manual Slicers: With these, you push the carriage back and forth yourself. They’re perfect for lower-volume shops or for slicing delicate cured meats where you want total control.

- Automatic Slicers: These have a motorized carriage that does the work for you, making them a lifesaver for high-volume jobs like slicing bacon or deli meats. They save a ton of time and keep your staff from getting worn out.

When you're picking a slicer, the blade size is a huge factor. A 12-inch blade is a fantastic, versatile choice for most butcher shops, big enough to handle everything from small salamis to larger roasts.

The Powerhouse: Commercial Meat Grinder

Freshly ground meat is a sign of a real, quality butcher shop. A heavy-duty commercial meat grinder lets you offer custom blends, control the fat content, and guarantee freshness—three things that immediately set you apart from the supermarket. Whether you're grinding chuck for classic burgers for a Los Angeles food truck or making a special sausage blend for a local restaurant, a powerful grinder is essential.

You'll want a grinder with at least a 1 HP motor to handle big jobs without overheating. Interchangeable grinding plates are another must-have, letting you switch between coarse, medium, or fine grinds to meet any customer's request. Just as important is how easily it comes apart for daily cleaning so you can keep your sanitation standards perfect. This machine is a true profit center, turning leftover trim into a high-demand, value-added product.

The need for this kind of precise and efficient equipment for butcher shop operations is only getting bigger. The global market for meat cutting machines was valued at around $3.5 billion in 2023 and is expected to hit $5.8 billion by 2032. This is all being driven by customers wanting fresher meat and shops needing to meet tougher food safety rules. You can find more insights on the meat cutting machines market and its projected growth over on Dataintelo.com.

Mastering Cold Storage and Refrigeration

In a butcher shop, your meat is your money. Simple as that. Protecting that inventory with the right cold storage isn't just a good idea; it's the absolute bedrock of your business. You're not just buying coolers—you're creating a complete cold chain that keeps meat safe and pristine from the moment it arrives to the second a customer takes it home.

This system of equipment for butcher shop refrigeration is more than just one big fridge. It’s a smart combination of different units, each playing a vital role in preserving quality, guaranteeing safety, and ultimately, making you sales. These commercial refrigerators and freezers are essential restaurant equipment, just as vital for a butcher shop as they are for a bustling Los Angeles eatery.

What you see here is a well-oiled machine. A proper commercial refrigeration setup is non-negotiable for any serious butchery. Combining walk-in storage for bulk inventory with easily accessible display cases is the secret to a workflow that’s both efficient and safe.

The Foundation: Your Walk-In Cooler

Think of the walk-in cooler as the bank vault for your meat. It's where you'll hang large carcasses, store primal cuts, and keep your bulk inventory at a perfectly stable, safe temperature. In a city like Los Angeles, where you might be supplying restaurants or handling massive deliveries, a dependable walk-in is a must-have.

When you're picking one out, zero in on these factors:

- Temperature Consistency: Your walk-in absolutely has to hold a steady temperature just above freezing, typically between 34°F and 38°F, with no major swings. This is what slows down bacterial growth without wrecking the meat's texture.

- Size and Shelving: Always plan for more space than you think you need right now. A well-organized walk-in with heavy-duty, NSF-rated shelving is crucial for letting air circulate around your product, which is essential for proper cooling.

- Humidity Control: If you’re thinking about starting a dry-aging program to cater to LA's high-end steakhouse crowd, you need precise humidity control. It’s the only way to safely develop those rich, concentrated flavors.

To get into the nitty-gritty of sizing and features, check out our guide on commercial walk-in refrigerators. It’s packed with details to help you make the right call.

Quick Access with Reach-In Units

While the walk-in handles the heavy lifting, your reach-in refrigerators and freezers are the workhorses of your daily grind. You'll want these positioned right near your processing area, holding the cuts you're working on throughout the day—think trim for the grinder or steaks ready for the display case.

This separation is a huge part of an efficient workflow. It means you’re not constantly opening the main walk-in, which keeps its temperature stable and your energy bill down. Plus, your team can grab what they need immediately without digging through your entire inventory.

The Salesperson: Your Refrigerated Display Case

Your refrigerated display case is so much more than cold storage; it's your #1 sales tool. This is the stage where your skill and craftsmanship shine, tempting customers with gorgeous cuts of meat. A sparkling clean, brightly lit, and perfectly functioning display case builds trust and encourages those impulse buys.

A great display case does two things perfectly: it keeps your product at a safe temperature (below 40°F) and makes it look incredible. It’s the final, crucial link in the cold chain that connects your hard work directly to the customer.

Look for models with features that boost both safety and sales:

- Gravity Coil Systems: These are the go-to for fresh meat. They maintain higher humidity, which stops the meat from drying out and losing its color.

- NSF Certification: This is mandatory. It’s your guarantee that the unit is designed for easy cleaning and will pass your health inspection.

- Energy Efficiency: Modern units with LED lights and better compressors can seriously cut down your monthly utility bills, which is a huge deal for any business.

Whether you're selling Korean BBQ short ribs or carne asada flank steak for Mexican dishes, how you present your products to the diverse communities of Los Angeles matters. Your display case is where your cuts become the star of the show, making it a critical piece of equipment for your butcher shop.

Creating Value-Added Products and Profits

The best butcher shops in Los Angeles have figured something out. They're not just places to grab a few steaks anymore; they've become culinary hubs that inspire home cooks and are essential suppliers for local restaurants. The secret? It's all about creating value-added products—turning inexpensive trim and basic cuts into high-margin items that don't take a ton of effort to make.

This is where your specialty equipment really starts to pay for itself. With just a few key machines, you can seriously expand what you offer, slash your waste, and tap directly into the wild and varied tastes of the LA food scene. From crafting custom breakfast sausages for a local diner to marinating meats perfectly for a Korean BBQ pop-up, this is the gear that transforms your shop from a simple meat counter into a creative powerhouse.

From Trim to Treasure With Sausage Stuffers

Every butcher has to deal with trim—those odd-sized bits and pieces left over after cutting beautiful steaks and roasts. A commercial sausage stuffer lets you take that trim, which you might have sold for cheap, and turn it into something special like house-made sausages that people will come back for again and again.

Think about it. You could offer a unique chorizo blend that local taco spots go crazy for, or maybe a Thai-inspired sausage with lemongrass and chili. This one piece of equipment opens up a massive world of creative—and profitable—ideas.

When you're looking for a sausage stuffer, keep these things in mind:

- Capacity: You’ll see models ranging from 5 to 30 pounds. A smaller one is perfect if you're just starting out with a few weekly specials, but if you plan on supplying other businesses, you'll need a larger one to keep up.

- Manual vs. Electric: Manual stuffers give you amazing control for small, artisanal batches. Electric models, on the other hand, are a must-have for pushing out larger quantities quickly and consistently.

- Stainless Steel Construction: Just like your other main processing equipment, a stainless steel stuffer is non-negotiable. It has to be durable and easy to clean, period.

This is your chance to play with flavors that connect with LA's diverse communities and create that signature product nobody else has.

Extend Shelf Life and Convenience With Vacuum Sealers

A commercial vacuum sealer is easily one of the most useful tools you can have in your shop. Its main job is to pull all the oxygen out of the packaging, which makes a huge difference in the shelf life of fresh meat. It stops freezer burn in its tracks and keeps the meat's color and flavor locked in.

A vacuum sealer does more than just preserve meat; it transforms it into a convenient, modern product. It allows you to sell pre-portioned, freezer-ready packs, meal kits, and sous-vide items that appeal to busy customers.

Imagine the possibilities right here in Los Angeles. You could sell pre-marinated bulgogi packs for K-town BBQ nights or seasoned carne asada that's ready to hit the grill. For customers who want incredible meals without all the prep, these products are an absolute game-changer. A solid vacuum sealer is essential for any butcher shop that wants to meet the demands of today's customers.

Develop Deep Flavors With Smokers

If you really want to get into craft butchery, a commercial smoker is your ticket. It allows you to produce high-end items like house-smoked bacon, all sorts of charcuterie, and beef jerky. These are the kinds of products that command a premium price and really establish your shop as a destination for quality. The unique flavors you can develop, like Chinese lap cheong or smoked brisket for LA's BBQ scene, will set you miles apart from any supermarket.

This whole category of specialty equipment is seeing huge growth. The global market for meat and poultry processing equipment—which includes things like slicers, dicers, and smokers—was valued at around USD 7.12 billion in 2025 and is expected to hit USD 10.98 billion by 2032. That growth is all about the industry shifting toward more diverse, customized products. You can read more about the meat processing equipment market trends to see how this could affect your business. Investing in this gear helps you get a piece of that expanding market.

Tools and Supplies for a Safe and Sanitary Shop

While big-ticket items like band saws and grinders get all the attention, it’s the smaller tools and sanitation systems that truly make or break a butcher shop. These are the workhorses of your daily operation, the gear that guarantees precision, safety, and a passing grade from the Los Angeles County health inspector.

Think about it this way: your reputation is built on the foundation of customer trust. A razor-sharp knife, a spotless cutting board, and a gleaming sink aren't just tools—they're a promise of quality and safety. They are absolute must-have equipment for butcher shop owners who are serious about their craft.

Essential Hand Tools of the Trade

Any butcher worth their salt will tell you that their craft is an extension of the tools in their hands. The right set of knives and implements makes breaking down primals safer, more efficient, and cuts down on costly waste.

Your day-to-day arsenal should always include:

- Boning Knives: Their thin, flexible blades are perfect for navigating around bone, ensuring you get every last bit of valuable meat.

- Cleavers: When you need to get through smaller bones and cartilage without firing up the band saw, a heavy-duty cleaver is your best friend.

- Cimeter Knives: With their long, curved blades, these are the go-to for portioning out beautiful steaks and roasts for your display case.

- Sharpening Systems: A dull knife is a dangerous liability. You absolutely need a sharpening stone to create a fresh edge and a honing steel to keep it perfectly aligned throughout the day.

The Backbone of Your Workspace

Your work surfaces are where the magic happens. From trimming brisket to grinding custom burger blends, this is where your products spend most of their time, so their quality and cleanliness are non-negotiable.

A properly outfitted workspace is built on durable, food-safe gear. We're talking high-quality, NSF-certified polyethylene cutting boards that won’t dull your knives or become a breeding ground for bacteria. It also means having certified scales for accurate weights and pricing, keeping things fair for both you and your customers.

The real centerpiece of your workspace is the prep table. It's where every cut begins and ends. A flimsy or hard-to-clean table is a direct threat to your workflow and sanitation standards.

This is why stainless steel is the undisputed king in any professional kitchen or butcher shop. It's non-porous, tough as nails, and incredibly easy to sanitize. If you want to dive deeper into what makes a great table, check out our guide to stainless steel kitchen prep tables.

A butcher's toolkit extends beyond the primary knives. To run a smooth, compliant operation, a whole host of smaller tools and sanitation supplies are needed daily. Below is a checklist of these crucial items that ensure precision, safety, and adherence to health codes.

Essential Hand Tools and Sanitation Checklist

| Item Category | Specific Examples | Primary Purpose |

|---|---|---|

| Specialty Knives & Saws | Meat hooks, hand saws, twine dispensers, meat tenderizers | Handling large cuts, portioning, trussing, and preparation. |

| Protective Gear | Cut-resistant gloves, aprons, non-slip footwear | Ensuring staff safety during cutting and processing tasks. |

| Measurement & Labeling | Food scales, thermometers, label guns, food-safe markers | Accurate portioning, temperature monitoring, and product tracking. |

| Cleaning Chemicals | Food-grade sanitizers, degreasers, all-purpose cleaners | Killing bacteria and keeping all surfaces free of grease and grime. |

| Sanitation Tools | Scrub brushes, squeegees, heavy-duty sponges, mops, buckets | Physical removal of debris and application of cleaning solutions. |

| Waste Management | Heavy-duty trash cans, liners, bone barrels | Proper disposal of waste and byproducts to maintain a clean environment. |

Having these items well-stocked and readily accessible isn't just a good idea—it's fundamental to the integrity and safety of your entire operation.

Non-Negotiable Sanitation Setup

Finally, let’s talk sanitation. This is the bedrock of your business. Los Angeles County has some of the strictest health standards in the country, and your sanitation station is your first and most important line of defense. There are no shortcuts here.

Your setup absolutely must include:

- Three-Compartment Sink: This is mandatory for the wash, rinse, and sanitize protocol for all your tools, cutting boards, and grinder parts.

- Designated Handwashing Stations: You need separate, fully stocked hand sinks that are easy for staff to get to. This is critical for preventing cross-contamination.

- Proper Cleaning Supplies: Stocking up on food-grade sanitizers, detergents, and degreasers is key to keeping every surface—from the floors to the display cases—impeccably clean and safe.

How to Budget and Finance Your Equipment

Outfitting a butcher shop in Los Angeles is a serious step, but with a smart financial roadmap, it’s completely manageable. The real key isn't just looking at the initial sticker price of your equipment for a butcher shop; it's about building a budget that will support your business for the long haul.

A solid plan comes down to balancing those immediate costs with long-term value. You'll need to figure out where to invest in brand-new, warrantied machinery and where you can strategically save with high-quality used gear. This approach helps you build a powerful, reliable workspace without draining all your starting capital right out of the gate.

New vs. Used Equipment: A Strategic Choice

Choosing between new and used restaurant equipment isn’t an all-or-nothing game. It’s about making smart decisions on a piece-by-piece basis. Think of it like building an investment portfolio—some assets need to be rock-solid and secure, while others can be more focused on value.

- Invest New Where It Counts: For your motor-driven workhorses like meat grinders, band saws, and your main commercial refrigerators and freezers, buying new is almost always the right move. That manufacturer's warranty is your safety net, protecting you from expensive repairs and downtime when you can least afford it.

- Save Smart on Passive Gear: You can find incredible deals on used equipment for items without a lot of complex moving parts. High-quality used stainless steel prep tables, shelving, and three-compartment sinks deliver the same function as new ones but at a fraction of the cost.

Leasing vs. Buying Equipment

Once you’ve picked out your gear, you have to decide how you’re going to get it. Buying outright and leasing are the two main paths, and each has its own benefits for a new butcher shop owner in a tough market like Los Angeles.

Leasing equipment can be a powerful strategy for conserving your initial startup capital. It allows you to get top-of-the-line gear with lower monthly payments, aligning your expenses with your cash flow as your business grows.

Let's break down the two approaches:

| Factor | Buying Outright | Leasing Through Financing |

|---|---|---|

| Upfront Cost | High initial cash outlay. | Low or no down payment required. |

| Ownership | You own the asset immediately. | You build toward ownership over time. |

| Flexibility | Less flexible; you're locked in. | Easier to upgrade to newer models. |

| Tax Benefits | Depreciation tax deductions. | Lease payments are often fully tax-deductible. |

For a lot of new businesses, especially food trucks or smaller shops where cash flow is king, leasing is a really attractive option. Here at Los Angeles Restaurant Equipment, we offer flexible lease-to-own financing that gets you the tools you need right now while helping you build business credit for the future.

The demand for efficient, reliable machinery is only going up. The meat processing equipment market was valued at over USD 7.8 billion in 2025 and is expected to hit USD 15.2 billion by 2035, with automatic equipment leading the way. You can discover more insights about the meat processing market to get a sense of how investing in modern tools can boost productivity and cut costs. This growth just goes to show how important it is to pick financing options that let you access the best equipment for the job.

Common Questions About Butcher Shop Equipment

When you're setting up a new butcher shop, a few questions always seem to pop up. Getting straight answers is key to investing your money wisely and building a solid business in the competitive Los Angeles food scene.

Most Critical Starting Equipment

While a big, powerful band saw is usually the first thing that comes to mind, your walk-in cooler is the real heart of the whole operation. It’s the silent workhorse that protects thousands of dollars in inventory, 24/7. If that cooler fails, you could face a catastrophic loss, making top-notch refrigeration your single most important asset for both food safety and your bottom line.

New Versus Used Equipment Strategy

The smartest move is usually a mix of both. For the heavy-duty, motor-driven machines like your meat grinders and saws, buying new is a solid investment. That manufacturer's warranty gives you peace of mind, and you can count on its reliability to prevent the kind of downtime that can seriously hurt a new shop.

On the other hand, you can find some fantastic deals on used "passive" equipment. Think about items like:

- Stainless steel prep tables

- Shelving units

- Three-compartment sinks

These pieces don't have moving parts or complex electronics, so a high-quality used one works just as well as a new one for a lot less cash. Just be extra careful when looking at used refrigeration—its reliability is just too critical to take a chance on.

Planning a Smart Workflow Layout

Your shop's layout should tell a story, guiding the product from your back door all the way to the front counter. A straight, logical path is the best way to cut down on cross-contamination risks and keep your team working efficiently.

Think of your shop's layout as a one-way street for your product. It should flow logically from receiving, to cold storage, through processing, and finally to the retail display, without ever needing to double back.

This means putting your receiving door right next to the walk-in cooler. From the cooler, the meat moves to the processing area with saws and grinders, then over to prep tables for final cuts, and finally into the refrigerated display cases for your customers. Make sure to leave plenty of room around each piece of equipment—not just for safety, but for the deep cleaning you'll need to do to meet Los Angeles County health codes.

At Los Angeles Restaurant Equipment, we provide the high-quality, reliable gear you need to build your butchery with confidence. From foundational refrigeration to essential processing machines, we offer transparent pricing and flexible financing to support your vision. Explore our full catalog and get your shop started on the right foot at https://losangelesrestaurantequipment.com.