A Guide to Manitowoc Ice Machine Troubleshooting

Share

When your Manitowoc ice machine suddenly goes quiet, it’s rarely a catastrophic failure. More often than not, the fix is surprisingly simple—it usually comes down to checking the power, the water, and making sure the unit hasn't kicked itself into 'safe mode'. These first Manitowoc ice machine troubleshooting steps can get you back up and running fast, often without needing to call in a pro.

Your First Steps When the Ice Machine Quits

In the middle of a dinner rush in a bustling Los Angeles restaurant—whether it's a high-volume Koreatown BBQ joint or a packed Thai Town spot—a dead ice machine is a full-blown crisis. But before you grab the phone to call for service, take a deep breath. A few quick checks can often solve the problem right then and there. Kitchens are chaotic places; things get unplugged, and settings get bumped.

The first, most basic check is always power. It seems too obvious, I know, but you’d be amazed how often a machine gets unplugged during a deep clean or the power switch is accidentally flipped. Make sure the unit is plugged in securely and the main power switch is flipped to "ON."

Verifying Power and Water Connections

Okay, so it’s plugged in and switched on. What’s next? Head to your circuit breaker panel. A commercial kitchen in Los Angeles is a power-hungry beast, with commercial refrigerators, freezers, and ovens all pulling a ton of electricity. It's easy for a circuit to trip during peak service. For a deeper dive, it's worth understanding overcurrent protection devices, as they're designed to prevent serious electrical damage. A quick flip of a breaker might be all you need.

If the power is solid, your next suspect is the water supply. An ice machine can't do its one job without a steady stream of H2O.

- Check the Main Valve: Find the water supply valve leading to the machine. Is it fully open? These sometimes get nudged partially closed during cleaning or maintenance.

- Inspect the Hose: Take a look at the water line itself. Are there any obvious kinks or tight bends? A crimped hose will choke off the water flow and shut the machine down.

- Water Filter Status: A clogged water filter is one of the most common culprits I see, especially in places with hard water. If that filter is blocked solid, water can't get through, and the machine will stop making ice.

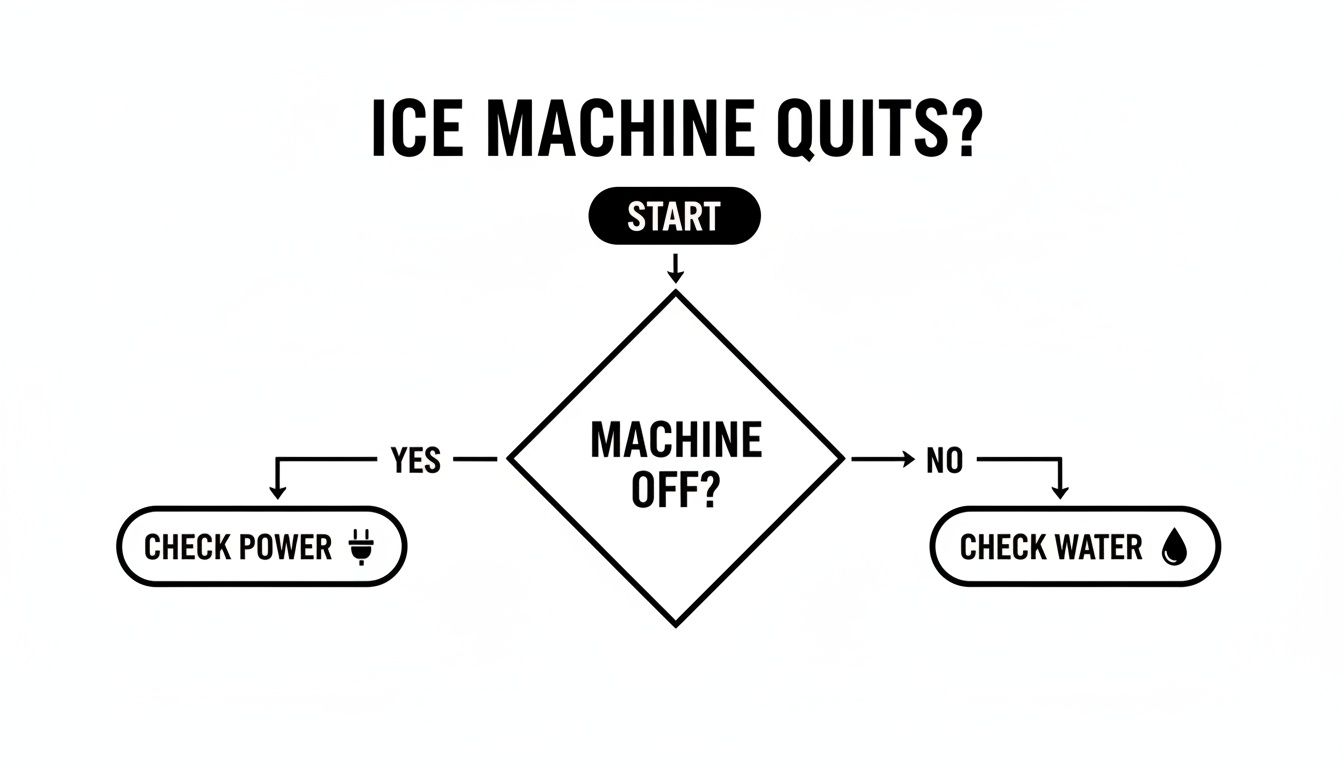

This simple decision tree lays out the first two things you should always check.

As you can see, working through power and water issues first will solve the vast majority of sudden shutdowns.

The Impact of the Los Angeles Environment

Running a kitchen in L.A. comes with its own set of challenges. The mix of high ambient heat, city dust, and airborne grease from your charbroilers and griddles can be brutal on restaurant equipment. All that gunk gets pulled into your ice machine and quickly clogs the condenser coils. A dirty condenser can't get rid of heat, causing the machine to overheat and shut itself off to prevent damage.

When a Manitowoc machine overheats or senses a problem that could cause real harm, it will often enter a 'safe mode' or hit a safety limit. This isn't the machine breaking; it's a warning. It’s telling you something needs attention before a small issue spirals into a major repair bill.

Making a habit of checking and cleaning the condenser is non-negotiable for any restaurant equipment maintenance plan in a city like Los Angeles. These initial diagnostic checks put you in control, helping you fix the most common problems and saving you precious time and money when the pressure is on.

Decoding Your Machine's Error Codes

When your Manitowoc ice machine starts flashing a code, don't panic. Think of it as your machine trying to tell you exactly what’s wrong, saving you from a frantic guessing game during a slammed dinner service. Learning how to read these alerts is a core part of Manitowoc ice machine troubleshooting for any manager in Los Angeles.

These codes might look like gibberish at first, but they often point to simple problems you can fix yourself, no service call needed. When you know what the codes mean, you can turn a potential disaster into a quick five-minute fix and get right back to serving customers.

Common Alerts in Los Angeles Kitchens

In the heat of an L.A. restaurant kitchen—whether it’s a Koreatown spot with multiple commercial freezers humming or a Japanese restaurant in Little Tokyo with non-stop foot traffic—a few error codes pop up more than others. Two of the most common culprits are E20 and Safety Limit 2.

- E20 (Water Probe Error): This alert means your machine is sensing either too much or too little water. This usually happens when mineral scale builds up on the water level probes, tricking the machine into a false reading.

- Safety Limit 2 (Long Harvest Cycle): This one is a big deal. It means the machine tried to release a sheet of ice, but it took too long. The number one reason? The ice is literally glued to a dirty evaporator plate.

Picture a Chinese restaurant in the San Gabriel Valley. The airborne starches from a busy wok station can easily settle on the evaporator plate. It creates a sticky film that makes it nearly impossible for the ice sheet to slide off, triggering that dreaded Safety Limit 2.

Interpreting E20 and Safety Limit 2

Error codes like E20 and Safety Limit 2 are especially common in busy L.A. bars where a steady supply of ice for cocktails is non-negotiable. Downtime stats show that a staggering 35% of service interruptions are tied to water system faults.

The E20 code points directly to a high or low water probe failure, usually because the water level is off—too high and it floods the trough, too low and it trips the sensor. This single issue affects 28% of units in high-volume establishments.

Meanwhile, a dirty evaporator, the main cause of Safety Limit 2, is noted as the top reason in 45% of harvest faults globally. That number jumps to 52% in dusty, urban markets like Los Angeles, where airborne flour from a Mexican tortilleria or residue from a Thai kitchen are just part of the environment.

When your Manitowoc gives you an error code, it’s not just beeping for no reason. It's giving you a specific clue to a fixable problem. The table below breaks down some of the most frequent codes we see in L.A. kitchens and what you should do about them.

Common Manitowoc Error Codes and Quick Fixes

| Error Code | Common Cause | Recommended Action |

|---|---|---|

| E01 | Stuck water pump relay | Check for a continuously running pump; may need a control board replacement. |

| E02 | Water dump valve relay stuck open | Inspect the dump valve to see if water is constantly draining. |

| E05 | High condenser temperature | Clean the condenser coil and ensure proper airflow around the unit. |

| E20 | High or low water probe failure | Clean the water level probes to remove mineral scale buildup. |

| Safety Limit 1 | Long freeze cycle | Check for low water flow, a dirty air filter, or a refrigeration issue. |

| Safety Limit 2 | Long harvest cycle | Clean the evaporator plate thoroughly with a nickel-safe cleaner. |

After you've tackled the root cause, a simple reset will usually clear the error and get your machine back to making ice.

A simple machine reset is often the first step after addressing an error code. To reset most Manitowoc models, simply turn the power switch to OFF, wait ten seconds, and then turn it back to ON. This clears the code from the control board's memory and allows the machine to start a new cycle.

What Your Machine Is Trying to Tell You

At the end of the day, these codes are your machine's cry for help, and they almost always point to a cleaning task or a simple adjustment. A Safety Limit 2 isn't just a random glitch; it’s a direct message that your evaporator plate is probably caked in scale or slime and desperately needs a good cleaning.

Ignoring these alerts is a recipe for disaster. They are designed to shut the machine down to prevent serious damage, like a compressor burning out from working too hard. By listening to what your machine is telling you, you can handle minor issues yourself. This proactive approach saves you from expensive service calls and ensures your Los Angeles restaurant—whether it's a food truck or a full-service dining room—never runs out of ice.

For more general tips that cover a wide range of issues, check out our guide on commercial ice maker troubleshooting.

Simple Fixes That Are Easy to Overlook

When your ice machine starts acting up in a busy Los Angeles kitchen, it's natural to think the worst. We immediately jump to conclusions like a busted compressor or a dead control board. But I've seen it time and time again—many frustrating ice machine problems come from surprisingly simple things that are easy to overlook. Before you dive deep into the technical manuals for your Manitowoc, just take a minute to check the basics.

Sometimes, the issue isn't even mechanical; it's all about the machine's environment. A few small tweaks to where your machine is placed can make a massive difference, especially for food trucks hitting L.A.'s streets or kitchens in older buildings with less-than-perfect floors.

The Critical Importance of a Level Machine

An ice machine that isn't level might not seem like a big deal, but it can set off a whole chain of problems. Picture a food truck parked on a slight hill in Silver Lake or an old restaurant in Downtown L.A. where the floors have settled over the years. Even a tiny tilt can completely disrupt the ice-making cycle.

When a Manitowoc isn't sitting perfectly flat, the water in the trough won't be even. This throws off the water level sensors, tricking the machine into thinking it has too much or not enough water. This one little issue can cause all sorts of headaches:

- Inconsistent Cube Size: Water can pool on one side of the evaporator plate, giving you cubes that are thick on one end and thin and watery on the other.

- Premature Harvest Cycles: The sensors might kick off the harvest cycle too soon, dropping an incomplete sheet of ice and killing your daily output.

- False Error Codes: An unlevel machine can sometimes trigger a false E20 water probe error, sending you on a wild goose chase for a problem that isn't there.

You'd be surprised how often this is the culprit. In fact, for L.A.'s mobile kitchens, an unlevel machine can slash ice production by 25-40%. Field data shows that a machine not sitting flat mimics a low water supply in 32% of service calls and is behind 22% of shallow cube complaints. Just grab a simple bubble level and adjust the leg levelers until it’s perfectly even.

Your Kitchen's Temperature Is Your Machine's Temperature

Another huge factor that often gets missed is the ambient temperature in your kitchen. Air-cooled Manitowoc machines need to pull in the surrounding air to cool the condenser and push out heat. When a Southern California heatwave hits and your kitchen feels like a sauna, your ice machine is suffering right there with your line cooks.

If the air it's pulling in is already hot, the machine has to work way harder to cool down and freeze water. This means longer freeze cycles and a lot less ice at the end of the day.

A Manitowoc's ice production is rated based on 70°F air and 50°F water. For every 10 degrees the air temperature goes up, expect your ice production to drop by about 10-15%. On a scorching 100-degree day in the Valley, you could be losing almost a third of your ice.

To fix this, make sure your machine has room to breathe—give it at least 6-8 inches of clearance on all sides for good airflow. Try not to stick it right next to the exhaust of a hot commercial refrigerator or a row of deep fryers. Keeping the machine's environment cool is just as important as keeping the machine itself clean.

If you’ve tried these simple but crucial checks and are still stuck, take a look at our guide for when your ice machine is not making ice to explore more advanced solutions.

A Practical Maintenance Routine That Works

Let's be honest, the best kind of Manitowoc ice machine troubleshooting is the kind you never have to do. A little bit of consistent maintenance is the single best way to dodge those emergency breakdowns. This is especially true in a place like Los Angeles, where your restaurant equipment is always working overtime.

This isn’t about becoming a certified technician. It’s about simple, repeatable tasks that will keep your ice clean, extend the life of your machine, and save you a lot of headaches.

The secret is just creating a schedule and sticking to it. A few minutes each day, a slightly deeper clean each week, and a thorough check once a month will prevent that dreaded moment when the ice bin is empty during a Saturday night rush.

Your Daily, Weekly, and Monthly Checklist

Consistency is your best friend here. Think of this routine just like prepping your station—it's a non-negotiable part of keeping things running smoothly, whether you're in a food truck in Venice or a fine dining spot in Beverly Hills.

Here’s a practical schedule you can start using right away:

-

Daily Tasks (2 minutes):

- Wipe Down Exterior Surfaces: Grab a food-safe cleaner and give the outside of the machine a quick wipe, paying attention to the door handle and other high-touch spots. It keeps kitchen grease and grime from building up.

- Inspect the Ice Bin: Just a quick look inside the bin is all it takes. Check for any early signs of mold or slime, and make sure the ice scoop is clean and stored properly outside the bin.

-

Weekly Tasks (10-15 minutes):

- Clean the Air Filter: If you have an air-cooled model, its filter is its first line of defense. Just slide it out, wash it with some warm, soapy water, let it dry completely, and pop it back in.

- Inspect and Clean the Condenser: This one is huge. A dirty condenser is one of the most common reasons for low ice production, accounting for up to 40% of service calls. When it gets clogged, it can slash your ice output by 30-50%, especially when things heat up past 90°F—a regular occurrence during an L.A. summer. You can get more details from this extensive Manitowoc troubleshooting guide from Parts Town.

A dirty condenser is like forcing your machine to wear a thick winter coat on a hot day. It can't get rid of heat, so it has to work way harder, straining the compressor and running up your energy bill long before it finally breaks down.

Performing a Deep Clean and Sanitization

About every six months, you need to set aside time for a full cleaning and sanitizing cycle. If you're running a high-volume spot—say, a busy ramen shop or a Mexican restaurant cranking out margaritas—you should probably do this more often. This process gets rid of the mineral scale (thanks, hard L.A. water) and biofilm that builds up in the machine's water system.

This is a critical food safety step. The ice you serve is food, and this deep clean makes sure it’s safe for your customers.

You’ll need a Manitowoc-approved, nickel-safe ice machine cleaner to break down the minerals, followed by a sanitizer to eliminate bacteria. Using the wrong procedure or a harsh chemical can destroy the evaporator plate, and that’s a very expensive replacement.

For a clear, step-by-step walkthrough of this essential process, check out our guide on how to clean a Manitowoc ice maker. Taking an hour to do this every few months is an investment that pays for itself by preventing service calls and keeping your machine running strong for years.

When It's Time to Call in the Pros

Look, I get it. In a busy Los Angeles kitchen, downtime is the enemy. This guide is all about empowering you to tackle the common hiccups with your Manitowoc ice machine yourself. But just as important as knowing what you can fix is knowing when to put the tools down and pick up the phone.

Trying to be a hero on a complex repair without the right training can quickly turn a simple fix into a catastrophic failure. That's a costly mistake, and it can even be dangerous. Your machine will usually give you some pretty clear signs that it's time to call in a certified technician.

Red Flags: Recognizing Serious Mechanical Failures

Some problems are more than just a dirty sensor. If you see, hear, or smell any of the following, your first move should be to shut the machine down to prevent more damage and call for professional service right away.

- Loud Grinding or Squealing: If your machine starts making awful grinding, screeching, or banging sounds, that's a major warning. These noises often point to failing bearings or a compressor that's about to give up. Don't just hope it goes away.

- A Smell of Burning Plastic or Wires: This one is non-negotiable. Any kind of electrical burning smell is a serious fire hazard. If it's safe to do so, unplug the unit immediately and call an expert. This could be anything from a failing motor to a short in the control board.

- Suspected Refrigerant Leaks: Refrigerant is hazardous stuff and requires special certification to handle. If you see an oily residue building up around the machine's components or notice the machine is running non-stop but producing no ice, you've likely got a leak.

These issues are out of your hands—they involve high-voltage electricity and sealed refrigeration systems that are strictly the domain of trained professionals.

A classic mistake I see is operators endlessly resetting a machine with a serious fault. If an error code pops right back up after a reset or you hear that grinding noise, forcing it to run can cause a chain reaction. You could turn a single part replacement into a full system overhaul.

When Your Best Efforts Aren't Enough

So, you've done everything by the book. You’ve cleaned the condenser, scrubbed the evaporator, and reset the control board, but the machine is still acting up. That’s another clear sign that the problem runs deeper than routine maintenance.

For instance, if you keep getting an E20 error code even after cleaning the water probes multiple times, the control board itself might be faulty and unable to read the sensors correctly. In the same way, if the machine is spotless but still gets stuck in a long harvest cycle (Safety Limit 2), you could be looking at a weak water pump or an issue with the harvest-assist mechanism—things a basic cleaning just won't fix.

Why You Need a Manitowoc-Authorized Technician

When you do make that call, make sure it’s to a service provider who is actually authorized by Manitowoc. For any restaurant or food truck in L.A., this is a big deal. Here's why:

- Warranty Protection: Using a random repair person can instantly void your manufacturer's warranty. That leaves you holding the bag for any future repair bills.

- The Right Parts: Authorized technicians use genuine Manitowoc parts. They fit perfectly and work as intended. Cheaper aftermarket parts might save a few bucks now, but they often fail early and can even damage other components.

- Real Expertise: These techs are factory-trained on your exact model. They know the quirks and can diagnose complex refrigeration and electrical problems fast, getting you back to making ice with minimal downtime.

Common Questions About Manitowoc Troubleshooting

Even with a good guide in front of you, specific questions always come up, especially when you’re staring at a half-empty ice bin during the dinner rush at your Los Angeles restaurant. Here are some quick, practical answers to the problems we hear about most from busy owners and managers trying to handle Manitowoc ice machine troubleshooting.

Why Is My Manitowoc Making Thin or Incomplete Ice?

If your machine is spitting out thin, hollow, or slushy ice, it almost always points back to a water issue or a dirty component. It's a common complaint we get from high-volume spots, like Mexican restaurants that need a mountain of solid ice for margaritas and soda fountains.

Your first stop should be the water filter. A clogged filter is the number one culprit because it chokes the water flow needed to build a solid ice slab. When not enough water cascades over the evaporator, you end up with weak, incomplete cubes.

Next, have a look at the water distribution tube. This is the part with all the little holes that spray water evenly across the evaporator plate. Mineral scale from L.A.'s hard water can easily clog these holes, causing dry spots on the plate and an uneven sheet of ice. A thorough cleaning of the entire water system is usually the perfect fix.

How Often Should My Ice Machine Be Professionally Serviced in Los Angeles?

For any busy L.A. establishment—whether it’s a food truck, a bustling cafe, or a full-service restaurant—we strongly recommend scheduling professional maintenance at least twice a year. The operating environment here is uniquely tough on equipment.

- High Ambient Heat: The Southern California climate forces your machine's refrigeration system to work much harder to keep up.

- Airborne Grease and Dust: Grease from commercial charbroilers and fryers, mixed with city dust, will quickly clog up condensers and air filters.

- Hard Water: Mineral buildup is a constant battle in L.A., and it can choke water lines and coat critical sensors, causing all sorts of errors.

A certified technician does more than just a standard cleaning. They’ll check refrigeration pressures, test electrical parts like relays and capacitors, and calibrate the ice thickness and water level probes back to factory specs. This proactive approach is the best way to prevent a catastrophic failure during your busiest season.

The Machine Is Running but the Ice Bin Is Empty. What Should I Check?

This is one of the most frustrating problems: you can hear the machine humming away, but the bin is bone-dry. If you can tell the unit is cycling but not actually dropping any ice, the issue is almost always heat-related.

First, make sure the machine has room to breathe. Air-cooled models need at least 6-8 inches of clearance on all sides for proper ventilation. If it’s squeezed into a tight corner next to a hot commercial freezer or oven, it’s essentially suffocating and its ice production will plummet.

The second—and most likely—cause is a dirty condenser. As we’ve mentioned, the condenser's job is to get rid of heat. If it’s covered in a blanket of dust and grease, it can't do its job, and the machine simply won’t get cold enough to make ice efficiently.

Finally, a dirty evaporator plate can cause the ice sheet to stick during the harvest cycle. The machine might be making a perfect slab of ice, but if it can't release it into the bin, the whole production process just stops. A deep clean and sanitizing cycle will usually solve this.

Can I Use Any Cleaner on My Manitowoc Ice Machine?

Absolutely not. This is a critical point that could save you from a very expensive mistake. You must only use a Manitowoc-approved, nickel-safe ice machine cleaner.

Many Manitowoc evaporators have a special nickel plating that resists corrosion and helps the ice slide off easily. Using the wrong kind of acidic cleaner, like many generic descalers, can permanently strip this protective coating.

Once that nickel is gone, the evaporator will start to corrode, and ice will stick to it relentlessly, triggering constant harvest cycle errors. The only fix at that point is a full evaporator replacement—a repair that can run into thousands of dollars. Always check your machine's manual and use the exact cleaner and sanitizer recommended to protect your investment.

For all your restaurant equipment needs, from commercial refrigerators to the best ice machines for your Los Angeles business, Los Angeles Restaurant Equipment has you covered. Explore our full catalog and find the reliable gear you need to keep your kitchen running smoothly.

Visit us at https://losangelesrestaurantequipment.com to learn more.