LA Restaurant Guide to Commercial Water Line Installation

Share

Getting your water line installation right is the lifeblood of any Los Angeles restaurant. It’s what ensures everything from your three-compartment sink to that high-volume ice maker runs without a hitch. A proper install is so much more than just connecting a few pipes; it demands careful planning, a solid understanding of LA health codes, and using the right materials to avoid leaks and shutdowns that can kill your business.

Your Blueprint for a Flawless Water Line Installation

Nailing your water line installation from day one is fundamental to the success of any foodservice spot in Los Angeles. It doesn't matter if you're setting up a Korean BBQ joint in K-Town, a high-end Japanese sushi bar, or a mobile Thai food truck hitting the streets of Venice—your plumbing is the quiet hero of your entire operation.

Think of this guide as your complete roadmap, breaking down the whole process from the initial sketches to the final sign-off from the inspector. A strategic approach isn't just a good idea; it's the only way to prevent the kind of disasters that can cripple a new restaurant. Things like nagging leaks, weak water pressure, or a sudden health code violation can shut you down before you even serve your first customer.

The Foundation of Your LA Kitchen

Imagine your water lines as the circulatory system for your kitchen. They feed the critical equipment that brings your menu to life and dictates your workflow. If that system is poorly planned, you’re just setting yourself up for major headaches later on.

Here’s why a solid plan is totally non-negotiable for LA restaurant owners:

- Equipment Performance: Commercial refrigerators with ice makers, under-counter freezers, and dishwashers all need reliable water access. The wrong pressure or flow can seriously damage that expensive restaurant equipment and even void the warranties.

- Food Safety: Clean water is everything. A professional installation prevents any risk of contamination, making sure your Chinese restaurant’s prep stations and your Mexican kitchen’s sinks meet those strict Los Angeles County health standards.

- Operational Efficiency: Every minute your kitchen is down because of a plumbing failure is lost revenue. A durable, well-thought-out system cuts down the risk of emergency repairs that bring service to a grinding halt.

Navigating the LA Landscape

Before you even think about cutting a pipe, every restaurateur in Los Angeles has to get a few key things straight. You'll need to do a thorough assessment of your equipment's water needs, take a deep dive into local city codes and permits, and pick materials tough enough for a commercial environment.

For example, when you're mapping out the installation, it's smart to weigh the long-term value of a full repipe against patching up old problems. Sometimes, choosing to repipe instead of repair is a much smarter investment in your restaurant's future.

A flawless water line installation isn't just about getting the water to flow; it's about future-proofing your business against plumbing nightmares and ensuring you're compliant from day one.

This guide will walk you through it, giving you the insights you need for a successful project that supports your culinary dream and can handle the daily grind of a busy kitchen.

Navigating LA Permits and Pre-Installation Planning

Before you even think about picking up a wrench, a successful water line installation for your Los Angeles restaurant comes down to solid planning. This isn't just about making things easier; it's about building a legal and efficient foundation for your entire kitchen. Get this part right from day one.

If you skip the prep work, you’re looking at expensive delays, failed inspections, and maybe even fines from the Los Angeles Department of Building and Safety (LADBS). For a Korean BBQ joint or a busy downtown cafe, a mistake here means you're behind before you even open.

Conducting a Thorough Site Assessment

First things first: you need to map out every single piece of restaurant equipment that needs a water connection. This is more than just the obvious stuff, like your three-compartment sink. You have to account for everything.

Get started by creating a detailed checklist. This list becomes the blueprint for your plumber and is a must-have for your permit application.

- Hot & Cold Equipment: Make a list of all commercial refrigerators with ice makers, standalone ice machines, dishwashers, and combi ovens. Each one has its own specific GPM (gallons per minute) demand.

- Beverage Stations: Don't overlook the espresso machines, soda fountains, and water filtration systems. These often need their own dedicated lines with particular pressure ratings.

- Sanitation & Prep: Count every hand sink, prep sink, and mop basin. Health codes often dictate where these have to go. Knowing the rules is vital—for example, you can dive deeper into requirements like the right mop basin faucet height in our other guides.

- Specialty Equipment: Does your Japanese spot have a station just for rinsing rice? Does your Thai kitchen use a high-powered wok range that has its own water faucet? These custom needs have to be in the plan from the very beginning.

With your list in hand, go physically mark where everything will be placed in your kitchen. This visual map helps you find the most direct routes for water lines, which cuts down on piping and helps maintain good water pressure.

The LA Permit Process Demystified

Dealing with the LADBS can seem like a headache, but it’s a step you can't skip. In Los Angeles, almost any new plumbing work requires a permit, whether you're running a new line to a commercial freezer or just installing a new sink.

Trying a water line installation without a permit is asking for trouble. An inspector can shut you down with a stop-work order on the spot, and you won’t be able to do anything until the right paperwork is filed and approved. As you plan, getting familiar with water meter installation requirements is another smart move, as this is something inspectors often look at.

A permit isn't just bureaucratic red tape. It's a safety net to ensure your installation is up to code, safe, and won't create a public health risk. The LADBS inspector is there to make sure your system can handle the intense demands of a commercial kitchen without failing.

Understanding Backflow Prevention: A Non-Negotiable

One of the most important things an LA inspector will check is your backflow prevention system. For any commercial kitchen, this is absolutely mandatory.

Backflow is what happens when contaminated water from your restaurant—say, from a sink drain or dishwasher—gets sucked back into the clean, public water supply. It’s a major health hazard.

To stop this, you have to install specific backflow prevention devices. The right one depends on the equipment:

- Air Gaps: This is the most basic method. It’s a physical space between a water faucet and the top edge of a sink basin. All sink faucets need one.

- Reduced Pressure Zone (RPZ) Assemblies: These are heavy-duty devices needed for high-risk connections, like the chemical dispensers on a dishwasher or the main water lines that feed a lot of equipment.

- Atmospheric Vacuum Breakers (AVBs): You'll often see these on things like hose spigots or utility sinks to prevent back-siphonage.

Your plumber will know which devices are right for your setup, but it’s good for you to understand why they're so important. For any high-volume restaurant, making sure your backflow prevention is installed correctly is the key to passing your final inspection without any issues.

Choosing the Right Materials for Your LA Kitchen

The pipes and fittings you choose are the very backbone of your Los Angeles kitchen’s plumbing. This isn’t just about passing inspection; it’s about protecting your big-ticket restaurant equipment like an Atosa commercial refrigerator or your under-counter freezers from a catastrophic leak. The reliability of your whole operation, from a high-volume Korean BBQ joint to a nimble food truck, really comes down to these basic materials.

This decision is more critical than ever. The global market for water pipes is booming, projected to jump from $24.3 billion in 2022 to a staggering $37.1 billion by 2028. This growth reflects a massive push to upgrade our aging infrastructure, a huge deal for commercial kitchens where clean water is non-negotiable for everything from prep sinks to ice makers.

In many places, old WWII-era pipes are being replaced at a sluggish rate of only 0.50% annually, which can seriously compromise the water purity essential for food safety. You can get more details on this trend from the experts at BCC Research.

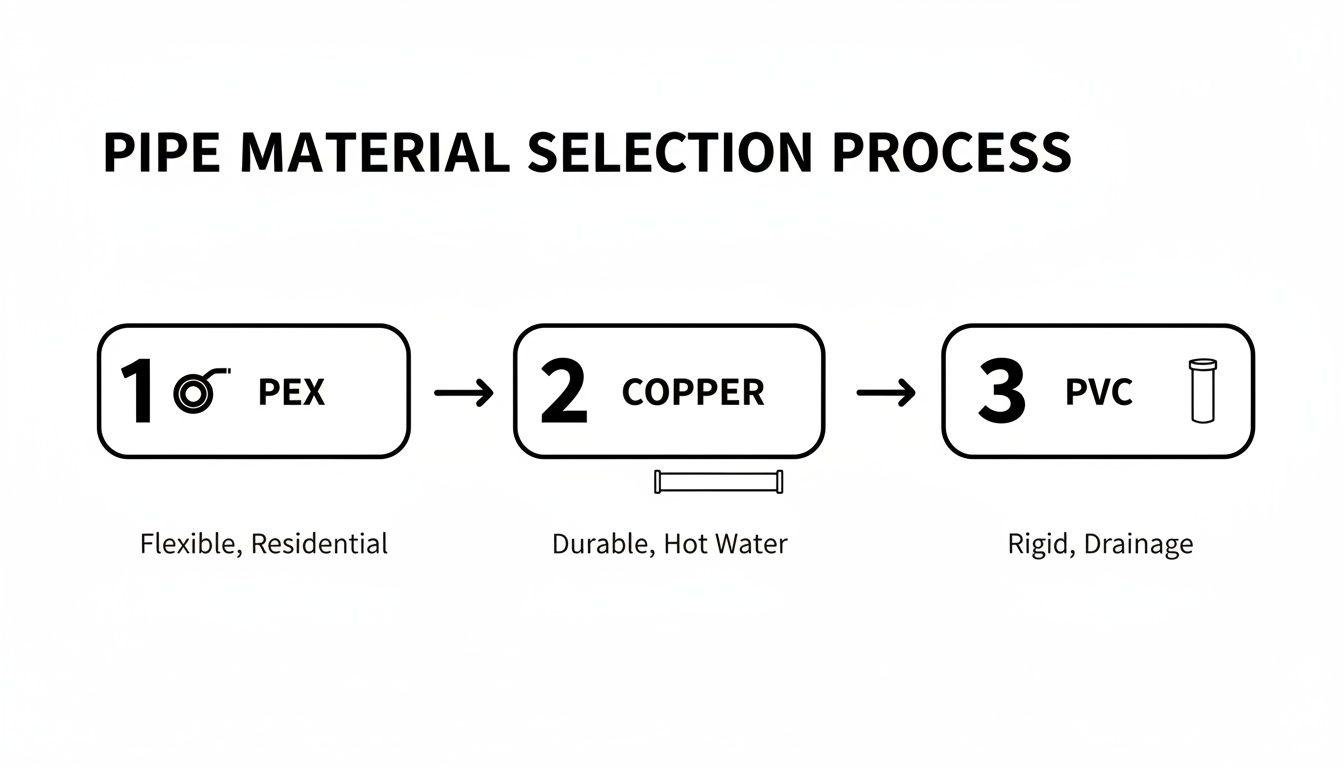

Commercial Water Pipe Material Comparison

In a busy LA kitchen, you'll mainly see a few types of piping. Each has its place, and the right one depends on whether you're running a hot line to a high-temp dishwasher or a cold line to your beverage station.

Picking the right pipe isn't a one-size-fits-all deal. It's a balance of cost, durability, and the specific demands of each water line in your kitchen.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| PEX | Cold water lines, tight spaces (food trucks), retrofits | Flexible, corrosion-resistant, cheaper, fast installation | Can't be exposed to UV light, not for high-heat areas |

| Copper | Hot water lines, connections near high-heat equipment | Extremely durable, naturally antimicrobial, handles high temps | Higher material cost, requires skilled soldering |

| CPVC | Hot and cold water lines in budget-conscious projects | Cost-effective, lightweight, corrosion-resistant | Can become brittle over time, less durable than copper |

For most LA restaurants, mixing and matching is the smartest play. You get the best of both worlds that way.

A hybrid approach is often the best bet for a busy downtown LA spot. Use tough-as-nails copper for the main hot water lines near your cooking suite, but take advantage of PEX's flexibility and lower cost for cold water runs through tricky walls and ceilings.

Your Essential Toolkit for Installation

Even if you’re hiring a plumber, knowing the tools helps you have an intelligent conversation about the job. And if you plan on tackling any of it yourself, this list is non-negotiable. A proper water line installation is all about precision, and having the right gear is what separates a solid, leak-free connection from a slow drip that can cause thousands in damage.

Here's what you'll find in any pro's toolbox:

- Pipe Cutters: You can't use just one. You'll need a dedicated tubing cutter for copper, a special PEX cutter for those clean, square edges, and a ratchet-style cutter for PVC.

- Deburring Tool: After any cut, this little tool is a lifesaver. It smooths out the inner and outer edges of the pipe, guaranteeing a perfect seal and preventing anything from messing with your water flow.

- Crimping/Clamping Tool (for PEX): This is the key to locking PEX fittings in place. Don't eyeball it—make sure you've got the correct size for the tubing you're using.

- Soldering Kit (for Copper): This is old-school but effective. The kit should have a propane torch, lead-free solder, flux, and some emery cloth to rough up and clean the pipe before you join it.

- Pipe Wrenches and Pliers: You can’t do much without a good set of adjustable wrenches and some channel-lock pliers for tightening down all the fittings and connections.

- Leak Detection Dye: This is a pro tip. Adding a little of this dye to the system when you're testing it makes even the tiniest pinhole leak glow under a UV light. It helps you catch a small problem before it turns into a full-blown disaster.

The Core Installation Process From Start to Finish

With your plans approved and your materials ready to go, it’s time to bring your kitchen’s plumbing to life. This is where a careful, step-by-step approach to your water line installation pays off down the road. A good setup ensures every single piece of restaurant equipment, from the ice maker in your commercial refrigerator to that high-temp dishwasher, gets the clean, reliable water it needs to run.

Think about setting up a brand-new multi-head espresso machine in a Silver Lake café. The very first thing you do is shut off the main water supply. This isn't just a suggestion—it's essential. Skipping this turns a straightforward job into a chaotic, water-logged mess that can cause serious damage to your kitchen.

Preparing the Work Area for Success

Once the water is safely off, your next move is to prep the area where you'll be working. This means clearing everything out of the way so you have easy access to all the connection points.

If you’re outfitting one of the many Los Angeles food trucks, this might involve popping off a few panels to snake the lines through the tight frame. In a brick-and-mortar Japanese restaurant, you might need to cut into a section of drywall to get to the main water lines.

Before you cut a single pipe, make sure to drain any existing lines. Just open the lowest faucet in the building and let gravity handle the rest. This prevents leftover water from messing up your connections. A clean, dry workspace is the first step to a leak-free installation.

This quick guide breaks down how to choose the right pipe material for different parts of your kitchen.

As you can see, PEX is great for flexibility, copper offers durability where heat is a factor, and PVC is best for specific drainage applications. A smart combination is often the best approach.

Making Secure and Lasting Connections

The strength of your entire water system comes down to the quality of your connections. The method you use will depend completely on the type of pipe you've selected. No matter which material you choose, you'll need the right tools and a steady hand to create a seal that can handle the constant pressure in a commercial kitchen.

For classic copper pipes, soldering is the way to go. Here’s how it works:

- Clean and Deburr: Use some emery cloth to scrub the outside of the pipe end and the inside of the fitting until they shine. A deburring tool will smooth out any rough edges from the cut, giving you a perfect fit.

- Apply Flux: Brush a thin, even layer of flux on both the pipe and the fitting. Flux is what helps the solder flow into the joint and create a super-strong bond.

- Heat and Solder: With a propane torch, heat the joint until it’s hot enough to melt the solder wire on contact. Just touch the lead-free solder to the joint, and it will get pulled right into the gap, forming a completely watertight seal.

For PEX tubing, the process is much quicker and doesn't require an open flame, which is why it's so popular in modern L.A. kitchens. The go-to method is crimping, which involves a special crimping tool and small metal rings.

Pro Tip: As you run your water lines, be sure to secure them every 32 to 48 inches with pipe hangers or clamps. This stops that annoying rattling noise (known as water hammer) and takes stress off the fittings, which is one of the biggest causes of slow leaks over time.

Routing Lines to Your Restaurant Equipment

Once your pipes are cut and your connections are solid, the last step is running the lines to your equipment. This is where all that planning really shines. For a Chinese restaurant's wok range, you'll likely need a dedicated cold water line with a gooseneck faucet. For a big ice machine, a solid connection is just as critical. For a more detailed walkthrough, you can learn more about connecting an icemaker to a water line in our dedicated guide.

Here are a few common scenarios you might run into in any Los Angeles kitchen:

- Food Truck Water System: In a food truck, you’re basically plumbing a small building on wheels—freshwater tank, pump, water heater, and sinks. PEX is a lifesaver here because it’s so flexible, letting you easily navigate tight corners and secure lines to the truck's frame.

- Commercial Dishwasher: Your high-temperature dishwasher will need its own dedicated hot water line. It’s a smart move to insulate this line with foam pipe sleeves. This keeps the water hot, helping your dishwasher run efficiently and meet health codes without wasting energy.

- Beverage Station: For equipment like a coffee brewer or soda fountain, you'll often want to install a water filter in-line. This protects your machines from mineral buildup, makes your drinks taste better, and helps your expensive restaurant equipment last longer.

Testing Your System and Passing Final Inspection

You’ve connected the last pipe, and your new water lines are in place. Now comes the most critical part of the job before your Los Angeles kitchen can officially open for business. This is where you verify everything—making sure every joint is sealed tight, the pressure is rock-solid, and the whole system can handle the grind of a busy service.

Don't rush this stage. Seriously. A slow, hidden leak behind a wall can lead to thousands in water damage and a nasty mold problem. Low pressure can turn your high-end restaurant equipment into expensive paperweights. For a bustling Mexican restaurant’s prep station or a high-volume Chinese spot’s wok range, perfect water flow isn't just nice to have, it's essential.

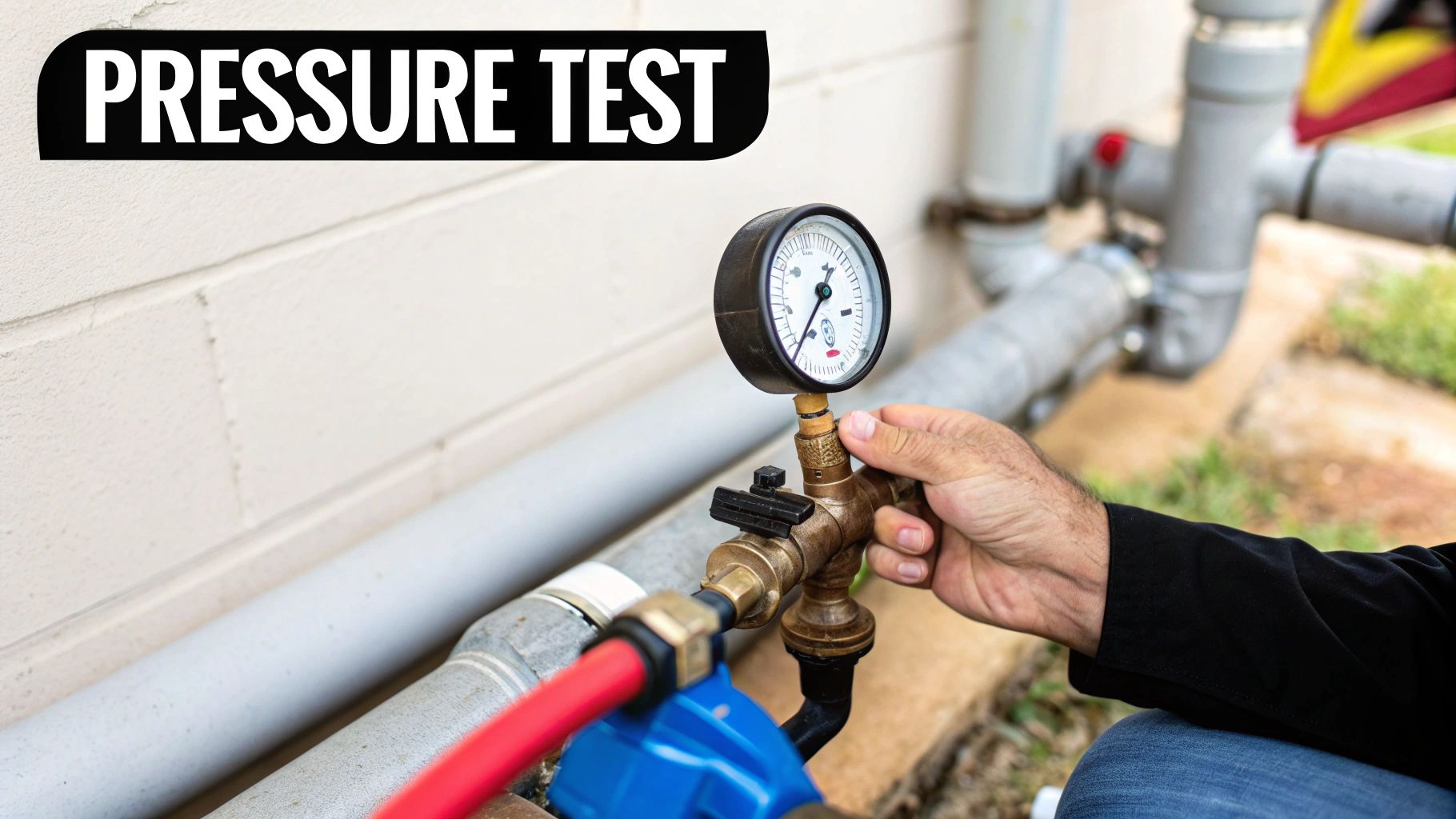

Pressurizing the System for a Leak Check

The gold standard for checking new plumbing is a pressure test. You’ll need to isolate the new lines, cap off the fixture outlets, and use a special pump to pressurize the system with either air or water. The target is usually around 100 PSI, and you’ll want to let it sit for a few hours.

The idea is simple: does the pressure hold? If that gauge needle moves even a little, you've got a leak somewhere.

Don't just look for drips. A proper pressure test is the only way to find those tiny, slow seeps that won't show themselves right away but can cause major headaches down the road for your commercial refrigerators, freezers, and floors.

Troubleshooting Common Installation Issues

Even the best of us run into a few snags during testing. Here are a few common ones you might see and how to handle them.

- Low Water Pressure: If the flow feels weak when you finally turn the water on, the first thing to check is that every single shutoff valve is fully open. If that’s not it, you might have an issue with pipe sizing—the pipes may be too small to supply all your equipment at once.

- Water Hammer: Hear a loud banging sound when a faucet is shut off quickly? That’s water hammer. It usually means the pipes aren't secured well enough. The fix is to add more pipe clamps to hold them steady or install a dedicated water hammer arrestor.

- Visible Drips: If you can see a leak at a threaded fitting, it's often a quick fix. Just apply more pipe thread sealant and tighten the connection properly. For soldered or crimped joints that are leaking, you’ll have to cut out the bad section and redo it.

Getting your plumbing to pass inspection is a huge win. It’s also part of a much bigger picture, as global spending on water and sewer line construction is expected to reach $260.6 billion by 2030. This massive investment is tackling aging pipes across the U.S., many of which are 75-100 years old and desperately need replacement. For a restaurant owner, a solid installation for equipment like a commercial dishwasher is key to staying open and avoiding costly downtime. You can explore detailed market reports to see the full scope of this trend.

Preparing for the Final LADBS Inspection

Once you've passed your own pressure test and fixed any problems, it’s time to call in the pros. You'll schedule your final inspection with the Los Angeles Department of Building and Safety (LADBS), and they'll send an inspector to make sure your work is up to code.

To make the inspection go as smoothly as possible, have these things ready:

- Your Approved Permit: The inspector will need to see it, so have it on-site and easy to find.

- Pressure Test Gauge: Don't take your test rig down. The inspector will want to see the gauge to verify the system held its pressure.

- Clear Access: Make sure the inspector has a clear path and view of all the new plumbing, especially the connections behind equipment.

The inspector will go over everything, from the backflow preventer at the start to the final stubs for your dishwashing machine for restaurants. Passing this inspection is the final hurdle. Once you get that green light, you can officially turn on the water and get your kitchen cooking.

Your Top Water Line Questions Answered

When you're running a restaurant or food truck in Los Angeles, plumbing questions are bound to pop up. Getting the right answers from the get-go is the best way to save yourself a lot of headaches and money down the road. Let's tackle some of the most common questions we hear from LA's incredible food community.

It’s a crucial topic, especially when you think about the state of our city's pipes. The global market for water infrastructure construction hit around USD 250 billion in 2023 and is expected to climb past USD 390 billion by 2032. A big reason for that growth is the need to replace old, failing pipes—some of which have been in the ground since World War II. With a replacement rate of just 0.50% a year in many places, a solid, modern installation for your business is more important than ever. You can dive deeper into these trends and get insights into the market dynamics here.

Do I Really Need a Permit Just to Hook Up an Ice Maker?

The short answer is: almost always, yes. Here in Los Angeles, any new plumbing or a major change to your existing lines requires a permit from the LADBS. That doesn't just mean a full kitchen build; it applies to adding a single new line for an espresso machine, a commercial dishwasher, or that new ice maker.

It’s always smartest to assume you need a permit. Trying to fly under the radar can lead to steep fines and stop-work orders that bring your project to a grinding halt.

What’s the Ballpark Cost for Installation?

This is where it really depends. The price can swing wildly based on how complex the job is, the materials you choose, and what local plumbers are charging. A simple hookup for one piece of restaurant equipment might only be a few hundred dollars. On the other hand, plumbing a whole new Korean BBQ joint from scratch could easily run into the thousands.

A few things that will move the price tag are:

- How much pipe you need to run.

- The type of pipe you choose (copper, for example, is usually pricier than PEX).

- How easy it is for the plumber to get to the work area.

Here's a pro tip: don't get fixated on the lowest upfront cost. Paying a bit more for a quality installation with durable materials—like using copper for lines near high-heat restaurant equipment—can save you from a burst pipe and an emergency shutdown right in the middle of a dinner rush.

Can I Just Use PEX Tubing for Everything?

PEX is a fantastic material, and we see it used all the time. It's flexible, durable, and perfect for navigating the tight corners of a Los Angeles food truck or a kitchen with a tricky layout. For cold water lines, it’s a go-to choice.

But it’s not a one-size-fits-all solution. For any lines running near high-heat restaurant equipment like commercial ovens or deep fryers, copper is often the required—and much safer—option. Always, always double-check the specific Los Angeles building codes for what materials are allowed in different parts of a commercial kitchen.

From planning your plumbing layout to finding the perfect restaurant equipment, Los Angeles Restaurant Equipment has your back. We’re your source for the professional-grade commercial refrigerators, cooking equipment, and prep tables that every successful LA eatery is built on. Shop our full catalog today!